Page 3059 - Flipbook_SolidDesignSoutheast2020

P. 3059

SWEEP ELBOWS

STANDARD 90 DEGRESS RADIUS

69 William Street, Belleville, NJ 07109 Sale Technical Sheet

PH: 973-759-4600 * Fax: 973-759-6449 STS Number ________

EMAIL: info@vac-u-max.com Effective Date _______

WEB SITE: www.vac-u-max.com Supersedes _________

D. SWEEP ELBOWS

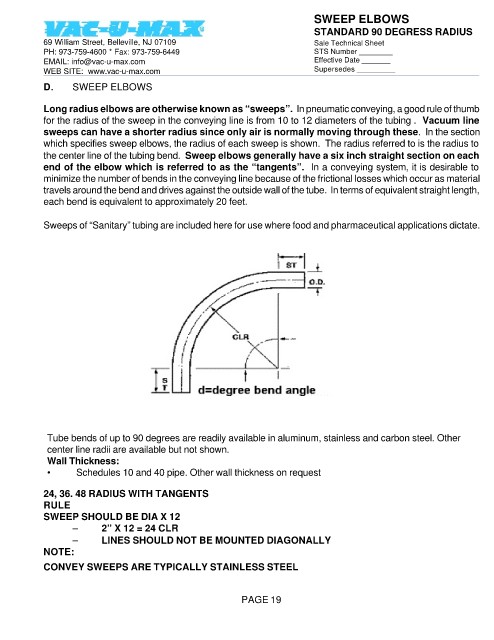

Long radius elbows are otherwise known as “sweeps”. In pneumatic conveying, a good rule of thumb

for the radius of the sweep in the conveying line is from 10 to 12 diameters of the tubing . Vacuum line

sweeps can have a shorter radius since only air is normally moving through these. In the section

which specifies sweep elbows, the radius of each sweep is shown. The radius referred to is the radius to

the center line of the tubing bend. Sweep elbows generally have a six inch straight section on each

end of the elbow which is referred to as the “tangents”. In a conveying system, it is desirable to

minimize the number of bends in the conveying line because of the frictional losses which occur as material

travels around the bend and drives against the outside wall of the tube. In terms of equivalent straight length,

each bend is equivalent to approximately 20 feet.

Sweeps of “Sanitary” tubing are included here for use where food and pharmaceutical applications dictate.

Tube bends of up to 90 degrees are readily available in aluminum, stainless and carbon steel. Other

center line radii are available but not shown.

Wall Thickness:

• Schedules 10 and 40 pipe. Other wall thickness on request

24, 36. 48 RADIUS WITH TANGENTS

RULE

SWEEP SHOULD BE DIA X 12

– 2” X 12 = 24 CLR

– LINES SHOULD NOT BE MOUNTED DIAGONALLY

NOTE:

CONVEY SWEEPS ARE TYPICALLY STAINLESS STEEL

PAGE 19