Page 308 - Flipbook_SolidDesignSoutheast2020

P. 308

Volumetric Feeders

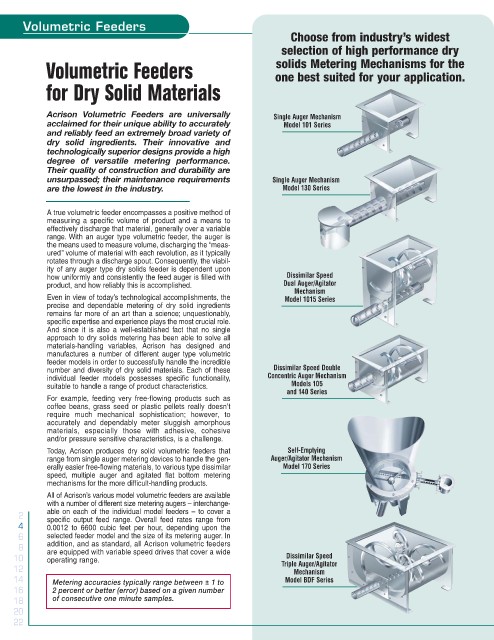

Choose from industry’s widest

selection of high performance dry

solids Metering Mechanisms for the

Volumetric Feeders one best suited for your application.

for Dry Solid Materials

Acrison Volumetric Feeders are universally Single Auger Mechanism

acclaimed for their unique ability to accurately Model 101 Series

and reliably feed an extremely broad variety of

dry solid ingredients. Their innovative and

technologically superior designs provide a high

degree of versatile metering performance.

Their quality of construction and durability are

unsurpassed; their maintenance requirements Single Auger Mechanism

are the lowest in the industry. Model 130 Series

A true volumetric feeder encompasses a positive method of

measuring a specific volume of product and a means to

effectively discharge that material, generally over a variable

range. With an auger type volumetric feeder, the auger is

the means used to measure volume, discharging the “meas-

ured” volume of material with each revolution, as it typically

rotates through a discharge spout. Consequently, the viabil-

ity of any auger type dry solids feeder is dependent upon

how uniformly and consistently the feed auger is filled with Dissimilar Speed

product, and how reliably this is accomplished. Dual Auger/Agitator

Mechanism

Even in view of today’s technological accomplishments, the Model 1015 Series

precise and dependable metering of dry solid ingredients

remains far more of an art than a science; unquestionably,

specific expertise and experience plays the most crucial role.

And since it is also a well-established fact that no single

approach to dry solids metering has been able to solve all

materials-handling variables, Acrison has designed and

manufactures a number of different auger type volumetric

feeder models in order to successfully handle the incredible

number and diversity of dry solid materials. Each of these Dissimilar Speed Double

individual feeder models possesses specific functionality, Concentric Auger Mechanism

suitable to handle a range of product characteristics. Models 105

and 140 Series

For example, feeding very free-flowing products such as

coffee beans, grass seed or plastic pellets really doesn’t

require much mechanical sophistication; however, to

accurately and dependably meter sluggish amorphous

materials, especially those with adhesive, cohesive

and/or pressure sensitive characteristics, is a challenge.

Today, Acrison produces dry solid volumetric feeders that Self-Emptying

range from single auger metering devices to handle the gen- Auger/Agitator Mechanism

erally easier free-flowing materials, to various type dissimilar Model 170 Series

speed, multiple auger and agitated flat bottom metering

mechanisms for the more difficult-handling products.

All of Acrison’s various model volumetric feeders are available

with a number of different size metering augers – interchange-

able on each of the individual model feeders – to cover a

2

specific output feed range. Overall feed rates range from

4 0.0012 to 6600 cubic feet per hour, depending upon the

6 selected feeder model and the size of its metering auger. In

addition, and as standard, all Acrison volumetric feeders

8

are equipped with variable speed drives that cover a wide

10 operating range. Dissimilar Speed

12 Triple Auger/Agitator

Mechanism

14 Metering accuracies typically range between ± 1 to Model BDF Series

16 2 percent or better (error) based on a given number

18 of consecutive one minute samples.

20

22