Page 685 - Flipbook_SolidDesignSoutheast2020

P. 685

NEW TO ALL-FILL:

UNSCRAMBLERS

All-Fill Unscramblers are designed and manufactured on a single frame with fixed change parts to ensure

quick and easy "tool-less" changeovers. Manufactured in a 'belt & hook' horizontal style or 'beltless'

compact, upright position. Containers sorted from bulk, oriented upright and discharged consistently

onto a conveyor or directly into a puck. Each All-Fill Unscrambler can be easily configured and upgraded

to ensure the right end solution. Decades of engineering and testing experience from Palace Packaging

engineers and sales team are now part of the All-Fill team and ready to discuss your project.

COMMON BOTTLE STYLES:

Food &

Cleaning

Soaps &

Detergents Cosmetics Pharmaceutical Shampoos Products Beverage Jars & Round Industrial

Containers

SPECIFICATION SUMMARY:

Standard Equipment Features Electrical Requirements

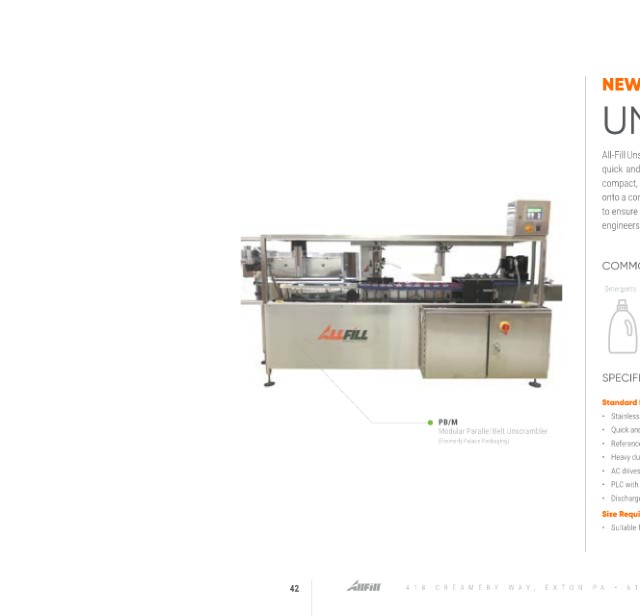

PB/M • Stainless steel construction • 110 volt, Single Phase, 60 hertz or 220volt, single phase,

60 hertz

Modular Parallel Belt Unscrambler • Quick and tool-less changeover

(Formerly Palace Packaging) • Reference scales for easy changeovers Pneumatic Requirements

• Heavy duty unscramblers • 80-90 psi

• AC drives on most models Custom Options

• PLC with color touchscreen • Bulk hoppers 4ft 3 to 100ft 3

• Discharge backlog sensor • Dust cover package

• Ionized air rinse

Size Requirements

• Suitable for containers up to 8" wide and 15" tall • Stack light

• Casters for portability

• Handle and finger grip orienting system

42 418 C REAMER Y W A Y , EXT ON P A • 610 . 524 . 735 • INFO @ ALL - FILL . C OM • WWW . ALL - FILL . C OM