Page 79 - Flipbook_SolidDesignSoutheast2020

P. 79

Model403Series of Weigh Feeders

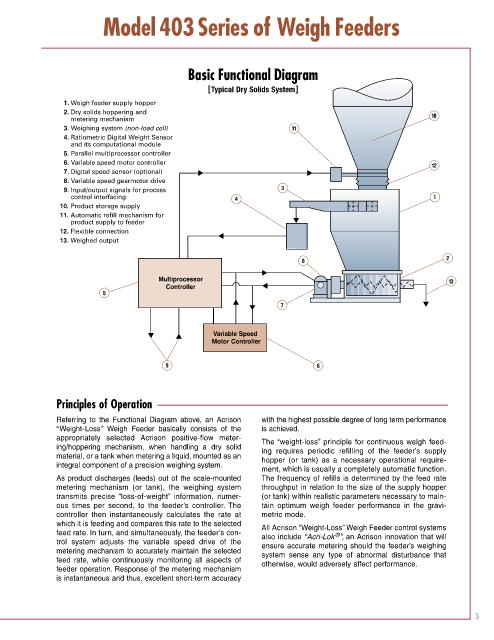

Basic Functional Diagram

[Typical Dry Solids System]

1. Weigh feeder supply hopper

2. Dry solids hoppering and

metering mechanism 10

3. Weighing system (non-load cell) 11

4. Ratiometric Digital Weight Sensor

and its computational module

5. Parallel multiprocessor controller

6. Variable speed motor controller

12

7. Digital speed sensor (optional)

8. Variable speed gearmotor drive

9. Input/output signals for process 3

control interfacing 4 1

10. Product storage supply

11. Automatic refill mechanism for

product supply to feeder

12. Flexible connection

13. Weighed output

2

8

Multiprocessor

13

Controller

5

7

Variable Speed

Motor Controller

9 6

Principles of Operation

Referring to the Functional Diagram above, an Acrison with the highest possible degree of long term performance

“Weight-Loss” Weigh Feeder basically consists of the is achieved.

appropriately selected Acrison positive-flow meter- The “weight-loss” principle for continuous weigh feed-

ing/hoppering mechanism, when handling a dry solid

ing requires periodic refilling of the feeder’s supply

material, or a tank when metering a liquid, mounted as an

hopper (or tank) as a necessary operational require-

integral component of a precision weighing system.

ment, which is usually a completely automatic function.

As product discharges (feeds) out of the scale-mounted The frequency of refills is determined by the feed rate

metering mechanism (or tank), the weighing system throughput in relation to the size of the supply hopper

transmits precise “loss-of-weight” information, numer- (or tank) within realistic parameters necessary to main-

ous times per second, to the feeder’s controller. The tain optimum weigh feeder performance in the gravi-

controller then instantaneously calculates the rate at metric mode.

which it is feeding and compares this rate to the selected

All Acrison “Weight-Loss” Weigh Feeder control systems

feed rate. In turn, and simultaneously, the feeder’s con- ®

also include “Acri-Lok ”, an Acrison innovation that will

trol system adjusts the variable speed drive of the ensure accurate metering should the feeder’s weighing

metering mechanism to accurately maintain the selected system sense any type of abnormal disturbance that

feed rate, while continuously monitoring all aspects of

otherwise, would adversely affect performance.

feeder operation. Response of the metering mechanism

is instantaneous and thus, excellent short-term accuracy

3