Page 1 - Master Cylinder Rebuild

P. 1

Inline Tube - Master Cylinder Rebuild

Today it is hard to decide to rebuild or buy new. Rebuilding is time consuming, messy and may still result in a leaky part. On some cars

and trucks it is the only solution since limited master cylinders are available. Rebuilding requires some common tools (Snap ring pliers)

and a parts cleaner unit or a sand blast cabinet. If you want a show quality part you will have to send out the cap and the straps to be

plated. If the unit is in good shape and the cylinder wall is not deteriorated it will be an easy rebuild. If the unit is rusty and pitted you

could be in for a long day. The bleeders could be rusted in place, the inside piston while riding smooth may not want to come

past where the cylinder wall is a bit rough. All this is compounded when a bleeder breaks off or other issues arise. Once you get the unit

apart you may find the cylinder wall to have small pits and this is bad news. While a few pits are ok, heavy pits under the seals will help

the fluid travel past the seals and cause the rebuilt unit to leak again. If the cylinder wall is bad, then it may need to be sleeved and this

costs more than the new unit. So you ask at this point why rebuild it? You do it for the ultimate matching numbers show car. The

original unit will have the manufacture logo, part number, and date code. If you want the car to be factory concourse correct rebuilding

is the only solution. If you are not concerned with these numbers don't waste your time. The new unit will have the exact shape and

performance as the original with the bleeders. These new units are very hard to tell from the originals but will not have the part numbers

and date codes. The new unit is ready to bolt on so you will save many hours of time.

Since rebuilding is not to common any more the rebuild kit is slightly cheaper than a new unit. With the rebuild kit running around

$30.00 and the new unit $70.00 but once you factor in your Saturday of time the clear winner is the new part, in a few hours you can be

driving the car again. By following the steps below you can rebuild your component just like an experienced mechanic. Inline Tube

offers all the pieces of the rebuild from the rubber seals to complete master cylinders ready to bolt onto your classic.

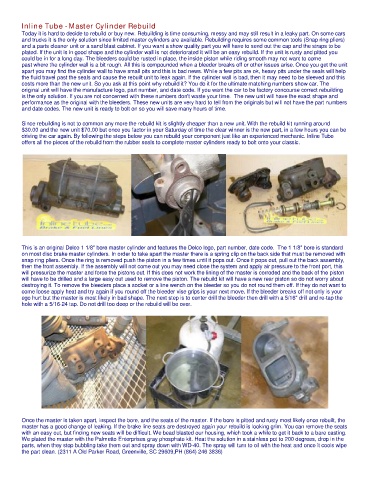

This is an original Delco 1 1/8" bore master cylinder and features the Delco logo, part number, date code. The 1 1/8" bore is standard

on most disc brake master cylinders. In order to take apart the master there is a spring clip on the back side that must be removed with

snap ring pliers. Once the ring is removed push the piston in a few times until it pops out. Once it pops out, pull out the back assembly,

then the front assembly. If the assembly will not come out you may need close the system and apply air pressure to the front port, this

will pressurize the master and force the pistons out. If this does not work the lining of the master is corroded and the back of the piston

will have to be drilled and a large easy out used to remove the piston. The rebuild kit will have a new rear piston so do not worry about

destroying it. To remove the bleeders place a socket or a line wench on the bleeder so you do not round them off. If they do not want to

come loose apply heat and try again if you round off the bleeder vise grips is your next move. If the bleeder breaks off not only is your

ego hurt but the master is most likely in bad shape. The next step is to center drill the bleeder then drill with a 5/16" drill and re-tap the

hole with a 5/16-24 tap. Do not drill too deep or the rebuild will be over.

Once the master is taken apart, inspect the bore, and the seats of the master. If the bore is pitted and rusty most likely once rebuilt, the

master has a good change of leaking. If the brake line seats are destroyed again your rebuild is looking grim. You can remove the seats

with an easy out, but finding new seats will be difficult. We bead blasted our housing, which took a while to get it back to a bare casting.

We plated the master with the Palmetto Enterprises gray phosphate kit. Heat the solution in a stainless pot to 200 degrees, drop in the

parts, when they stop bubbling take them out and spray down with WD-40. The spray will turn to oil with the heat and once it cools wipe

the part clean. (2311 A Old Parker Road, Greenville, SC 29609,PH (864) 246 3836)