Page 2 - Master Cylinder Rebuild

P. 2

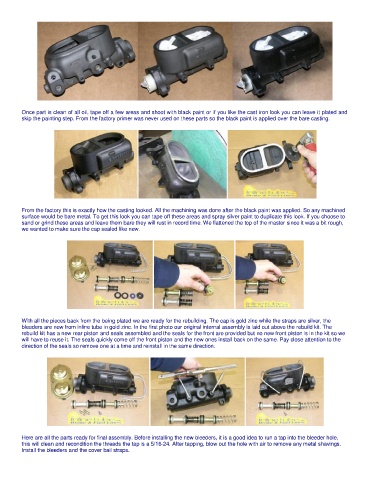

Once part is clean of all oil, tape off a few areas and shoot with black paint or if you like the cast iron look you can leave it plated and

skip the painting step. From the factory primer was never used on these parts so the black paint is applied over the bare casting.

From the factory this is exactly how the casting looked. All the machining was done after the black paint was applied. So any machined

surface would be bare metal. To get this look you can tape off these areas and spray silver paint to duplicate this look. If you choose to

sand or grind these areas and leave them bare they will rust in record time. We flattened the top of the master since it was a bit rough,

we wanted to make sure the cap sealed like new.

With all the pieces back from the being plated we are ready for the rebuilding. The cap is gold zinc while the straps are silver, the

bleeders are new from inline tube in gold zinc. In the first photo our original internal assembly is laid out above the rebuild kit. The

rebuild kit has a new rear piston and seals assembled and the seals for the front are provided but no new front piston is in the kit so we

will have to reuse it. The seals quickly come off the front piston and the new ones install back on the same. Pay close attention to the

direction of the seals so remove one at a time and reinstall in the same direction.

Here are all the parts ready for final assembly. Before installing the new bleeders, it is a good idea to run a tap into the bleeder hole,

this will clean and recondition the threads the tap is a 5/16-24. After tapping, blow out the hole with air to remove any metal shavings.

Install the bleeders and the cover bail straps.