Page 3 - Soitaab Product Overview 2025

P. 3

7.000 m² (75400 sqft)

EXISTING Assembly Hall, Design, Service Dept

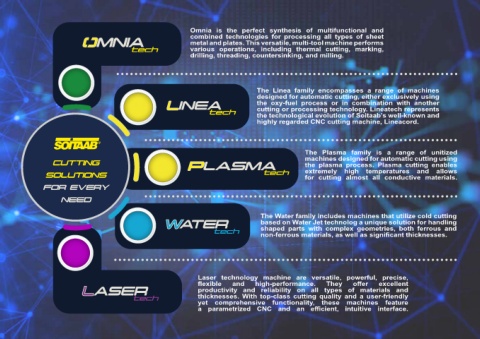

FACILITY 8.000 m² (86111 sqft) Omnia is the perfect synthesis of multifunctional and

combined technologies for processing all types of sheet

Machine Tools, Headquarter and Sales metal and plates. This versatile, multi-tool machine performs

various operations, including thermal cutting, marking,

drilling, threading, countersinking, and milling.

6.000 m² (64583 sqft)

NEW FACILITY Sheet Metal Cutting

Welding The Linea family encompasses a range of machines

Heat Treatment designed for automatic cutting, either exclusively using

Grinding and Painting the oxy-fuel process or in combination with another

cutting or processing technology. Lineatech represents

the technological evolution of Soitaab’s well-known and

highly regarded CNC cutting machine, Lineacord.

The Plasma family is a range of unitized

CUTTING machines designed for automatic cutting using

the plasma process. Plasma cutting enables

COMPANY MISSION extremely high temperatures and allows

Since its founding in 1938, the SOITAAB Group has grown to become Technological Innovation SOLuTIONS for cutting almost all conductive materials.

a world-leading manufacturer of CNC industrial cutting machines. FOR EVERY

Our greatest challenge is to always focus on technological innovation, With over 85 years of experience in the field, SOITAAB believes in

which has enabled us to become one of the global leaders in the field continuous technological development and the constant pursuit of NEED

of CNC industrial cutting machines. innovative cutting solutions, aiming to consistently achieve the highest

levels of efficiency, precision, and speed. The Water family includes machines that utilize cold cutting

The technologies we have developed and our production lines for based on Water Jet technolog a unique solution for handling

shaped parts with complex geometries, both ferrous and

plasma, flame, waterjet, laser, and bandsaw machines work in perfect Quality and Efficiency of Production Processes non-ferrous materials, as well as significant thicknesses.

harmony and interaction.

Thanks to its modern facilities in Milan, SOITAAB manages every

SOITAAB offers the widest range of cutting technologies available on aspect of production in-house, from design and mechanical proces-

the market—a competitive advantage that allows us to grow steadily sing to assembly and testing of each product. This unique and meticu-

and provide our customers with the most comprehensive and lous process ensures the highest quality and efficiency.

flexible technological solutions. Laser technology machine are versatile, powerful, precise,

flexible and high-performance. They offer excellent

productivity and reliability on all types of materials and

thicknesses. With top-class cutting quality and a user-friendly

yet comprehensive functionality, these machines feature

a parametrized CNC and an efficient, intuitive interface.