Page 5 - Drivalink

P. 5

The most Innovative System that brings together all Ensure your vehicle and drivers are ready for work with 360-degree Cameras Onboard Tablet

elements of Driver Safety, Truck Safety and Maintenance. proactive fatigue management, speed management, Our 360 cameras allows you to view video of the outside of the vehicle

and is uploaded to the server to allow viewing by central control. These

cameras are fitted with a view of the front, sides and rear of your vehicles

harsh driving reporting, Vehicle check report, License eliminating blind spots and lowering impact incidents.

When an indicator is activated the camera display will show in full screen

the side of the vehicle that is turning, it also displays in full screen the

No legacy systems validity check via the RMS and fit-for-duty declaration. reversing camera when the vehicle is put into reverse.

Axle Weights

One stop shop...we do it all Drivalink provides axle weights for all trucks allowing proper distribution of

loads across all axles.

GEO Fencing

Truck routing as standard with turn by turn DRIVALINK We can also give weights in and out of the Geo-fence, giving you Total Weight of trucks and trailers

accurate data of exact amounts of material entering a site as well as Drivalink also monitors total weight on all vehicles including Rigid,

Combination and Multi-combination vehicles. We also enable PDF’s to

Automated RMS check for Licencing STANDARD weights after unloading. send via email or SMS to the customer as proof of delivery.

Within custom Geo-fences we are able to monitor and set

customized speeds for low site speeds in high traffic pickup or

INCLUSIONS delivery zones Refrigeration

Larger display screens in the vehicles We can add sensors to monitor refrigeration temperatures with alerts.

All these reports are provided live both on your drivers Drivalink

performance dashboard and on your Drivalink web platform. Also

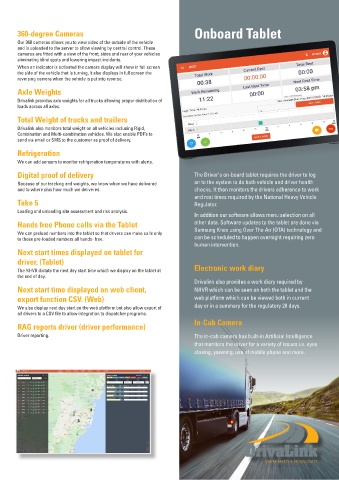

with a ‘history replay’ function and ‘waypoint management’. Digital proof of delivery The Driver's on-board tablet requires the driver to log

360 degree Cameras In-Cab Camera Pre-start check allowing photos Because of our tracking and weights, we know when we have delivered on to the system to do both vehicle and driver health

with artificial intelligence to be sent to dispatch Driver information and to where plus how much we delivered. checks. It then monitors the drivers adherence to work

With one click on the GPS maps, the dispatcher can easily access

We incorporate a standard or customizable pre-start checks on our timely and accurate driver information. This provides real time data Take 5 and rest times required by the National Heavy Vehicle

system. Our tablets have the added ability to take images of any on address location, license expiry, next medical date and work Regulator.

Individual Axle and Gross Axle weights issues via the tablet which are then sent to the web platform allowing option.There is even a solo or dual driver option available.. Loading and unloading site assessment and risk analysis.

dispatchers, safety, maintenance or management personnel to view and In addition our software allows menu selection on all

make an informed decision on proceedings before commencing any Over speed alerting Hands free Phone calls via the Tablet other data. Software updates to the tablet are done via

Latest technology that is heavily works. Any vehicle that exceeds the over speed threshold will alert the We can preload numbers into the tablet so that drivers can make calls only Samsung Knox using Over The Air (OTA) technology and

can be scheduled to happen overnight requiring zero

integrated to the Canbus Pre-start check fit for duty declarations driver every 15 seconds until the speed is reduce to the threshold to those pre-loaded numbers all hands- free. human intervention.

set. SMS’s can also be sent to management at preconfigured

The drivers are asked to verify that they are fit for duty therefore

ensuring that CoR is implemented, this includes drug and alcohol intervals. Next start times displayed on tablet for

KISS principle used in the development questions. Driver Fatigue Monitoring driver, (Tablet) Electronic work diary

of our solutions Pre-start check to the RMS DrivaLink by incorporating the Nation Heavy Vehicle Regulator The NHVR dictate the next day start time which we display on the tablet at

(NHVR) rules into our system means that the drivers no longer have

the end of day.

Drivalinks system connects to the RMS NSW to check license is Drivalink also provides a work diary required by

valid. Alerts necessary management if the driver declines to consent to work out when to take rest breaks or when they have exceeded

to RMS license check or if the license has expired. the daily allowable work time. This is completely automated for Next start time displayed on web client, NHVR which can be seen on both the tablet and the

the driver and is displayed on a fixed tablet within the cab of the

DrivaLink can also if requested disable the truck to ensure it isn’t truck with alerts that notify the driver 1 hour prior to a rest period export function CSV. (Web) web platform which can be viewed both in current

driven by an unlicensed driver. We are also talking to Ausroads who needed and then again every 15 mins until the break is taken. This We also display next day start on the web platform but also allow export of day or in a summary for the regulatory 28 days.

have a system called NEVDIS (National Ex- change of Vehicle and information is also easily viewed from your web platform. all drivers to a CSV file to allow integration to dispatcher programs.

Driver Information System) which would allow license checking

Australia wide. Driving reporting RAG reports driver (driver performance) In-Cab Camera

Advanced GPS tracking Driving reports are available for all metrics of your fleet, Driver reporting. The in-cab camera has built-in Artificial Intelligence

Advanced truck routing GPS maps with Geo-fencing. including… that monitors the driver for a variety of issues i.e. eyes

closing, yawning, use of mobile phone and more.

DrivaLink

DRIVER SAFETY & PRODUCTIVITY