Page 87 - C:\Users\CAN\Documents\Flip PDF Professional\Havaş Üniforma Kataloğu 2020\

P. 87

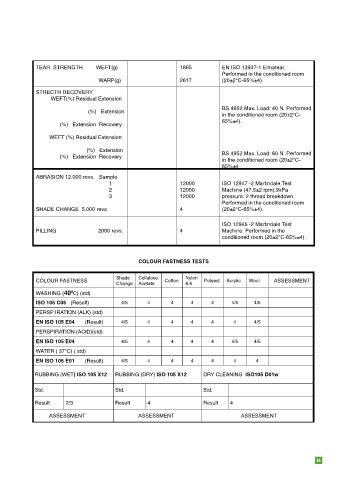

TEAR STRENGTH WEFT(g) 1865 EN ISO 13937-1 Elmatear.

Performed in the conditioned room

WARP(g) 2617 (20±2°C-65%±4).

STRECTH RECOVERY

WEFT(%) Residual Extension

BS 4952 Max. Load: 40 N. Performed

(%) Extension in the conditioned room (20±2°C-

65%±4).

(%) Extension Recovery

WEFT (%) Residual Extension

(%) Extension BS 4952 Max. Load: 60 N. Performed

(%) Extension Recovery

in the conditioned room (20±2°C-

65%±4

ABRASION 12.000 revs. Sample

1 12000 ISO 12947 -2 Martindale Test

2 12000 Machine (47.5±2 rpm).9kPa

3 12000 pressure. 2 thread breakdown.

Performed in the conditioned room

SHADE CHANGE 5.000 revs 4 (20±2°C-65%±4).

ISO 12945 -2 Martindale Test

PILLING 2000 revs. 4 Machine. Performed in the

conditioned room (20±2°C-65%±4).

COLOUR FASTNESS TESTS

Shade Cellulose Nylon

COLOUR FASTNESS Cotton Polyest Acrylıc Wool ASSESSMENT

Change Acetate 6.6

0

WASHING (40 C) (std)

ISO 105 C06 (Result) 4/5 4 4 4 4 4/5 4/5

PERSP IRATION (ALK) (std)

EN ISO 105 E04 (Result) 4/5 4 4 4 4 4 4/5

PERSPIRATION (ACID)(std)

EN ISO 105 E04 4/5 4 4 4 4 4/5 4/5

WATER ( 37°C) ( std)

EN ISO 105 E01 (Result) 4/5 4 4 4 4 4 4

RUBBING (WET) ISO 105 X12 RUBBING (DRY) ISO 105 X12 DRY CLEANING ISO105 D01w

Std. Std. Std.

Result 2/3 Result 4 Result 4

ASSESSMENT ASSESSMENT ASSESSMENT

85