Page 28 - CFCM Jan-Feb-2021_Neat

P. 28

INDUSTRIAL FINISHING: AEROSPACE COATINGS

HOW AUTONOMOUS ROBOTICS

TECHNOLOGY ENABLES

A RETHINK FOR AEROSPACE

COATING PROCESSES

By Robert Ravensbergen

inishing and coating processes are in part so demanding then proceed to its goal. Manipulation – in this case we’re truly

because they are so visible. Customers and end users for thinking of “C3PO” type machines – refers to how the robot would,

Fproducts expect consistent and defectless outputs for new in our example, pick up the cup, carry it and place it down again.

or refinished products and hence expect parts or finished goods to In the case of autonomy for value-added processes, localization

be flawless upon delivery. specifically requires an identification of where the robot and the

The scale of customer expectations isn’t the only coatings part being processed are placed. The planning involves process

challenge specific to the aerospace industry either. Specific constraints and the manipulation involves the execution of action

measurements and compliance needs make each process tedious on a spray gun or nozzle to achieve a specified outcome.

and unique, which becomes all the more difficult in the face of Obviously, a range of understanding can apply here, but in the

continued shortages in the highly refined skilled labor to meet case of spray finishing processes, precision is usually not required

production goals. below one millimeter for accuracy approximating that of a skilled

While automation solutions exist for coatings – whether using human operator to be achieved. With advances in a variety of tech-

reciprocating arms or robotization in high-volume operations – the nologies, including sensor fusion, multiple 3D sensors can be used

automation is rarely flexible enough to meet the precise demands to simultaneously identify the position, shape and orientation of

found in aerospace parts. Low-programming solutions like an complex shapes and parts – including concave parts.

automated booth don’t adapt enough to concave or complex part In this case, where the “loop is closed” and all sensor data is

shapes, and still produce rework, while robotic solutions that connected to a robot equipped to generate its own motion program –

require extensive programming will rapidly become too expensive the same way a self-driving car has the processing power to know

as changeover becomes more frequent. when to turn left or right – a robot can subsequently plan out opera-

In this circumstance, autonomous robots may offer a way forward tions to maximize the probability of a consistent output. Instead of

for high-compliance, high-mix coatings processes. Much the same behaving the way a human does, where a loose plan or methodology

way autonomy is bringing new efficiency to self-driving cars and might be subject to change, a robot can adhere to specific instruc-

materials handling, autonomous technology for value-added tions in an unpredictable band of scenarios with the same “robotic”

processes can effectively drive a process forward to achieve maxi- precision that robots are of course known for.

mum consistency and productivity without the wait – the technol-

ogy is already available today, thanks primarily to the constraints and

specific needs of value-added processes which permit a market-

ready solution to be more rapidly delivered. In all cases, this enables

a rethink of coatings processes. Not just on consistency and quality

improvements, but also on the variety and order of parts coating,

improved efficiency across finishing lines and the ability to specify

parts within value-added processes.

Consistency and Quality Improvements

Autonomous robots generally require one input – a goal set– and

the subsequent resolution of three core problems: localization,

planning and manipulation. A goal could be “pick up that cup and

put it on the table across the room”.

Localization would then refer to the robot’s ability to identify its

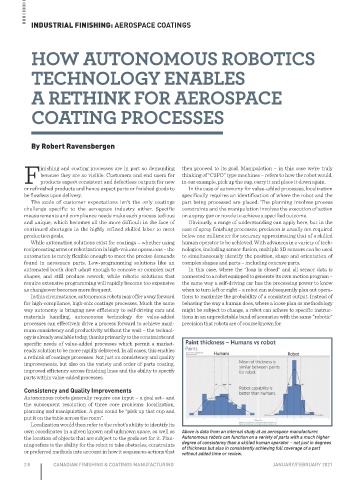

own coordinates in a given known and unknown space, as well as Above is data from an internal study at an aerospace manufacturer.

the location of objects that are subject to the goals set for it. Plan- Autonomous robots can function on a variety of parts with a much higher

ning refers to the ability for the robot to take obstacles, constraints degree of consistency than a skilled human operator – not just in degrees

of thickness but also in consistently achieving full coverage of a part

or preferred methods into account in how it sequences actions that

without added time or review.

28 CANADIAN FINISHING & COATINGS MANUFACTURING JANUARY/FEBRUARY 2021