Page 34 - CFCM Jan-Feb-2021_Neat

P. 34

INDUSTRIAL FINISHING: UV CURING SYSTEMS

REALITIES IN THE MECHANICAL

TUBE MARKETPLACE

By Michael Kelly

elivering the best product to your end customer is key in UV coatings, since percent solids for water-based range from 18

today’s manufacturing environment and has been a percent to 30 percent; but you also get less coverage per gallon.

Dcontinuing message for North American manufacturing This is where the ROI calculator in Table 1 will assist you in

companies. This is not new by any means but is receiving more understanding coverage per gallon when comparing water-based

emphasis and attention as end customers are more involved in coatings to UV coatings.

their suppliers’ manufacturing supply chain.

In the mechanical tube marketplace, this is defined as the The UV Alternative

following: Ultraviolet coatings technology offers a unique opportunity to

dramatically improve your manufacturing process, improve your

• Reduced overall product cost – a reduction of overall pricing sustainability footprint, and deliver actual ROI – less coating cost

/ measured in reduction of price per linear foot. per linear foot of pipe or tube.

• Continually improved product performance – increased Mechanical tube manufacturers are quick to embrace UV

white and red rust protection / measured by increased hours coatings once a detailed cost analysis is completed, as outlined

of ASTM B117 Salt Fog exposure. further in this article.

• Embracing a sustainable manufacturing process –

improved sustainability in the manufacturing process would Reduced Overall Product Cost

equate to less emissions / measured as an overall reduction in

VOCs and HAPs (Volatile Organic Compounds and Hazard-

ous Air Pollutants)

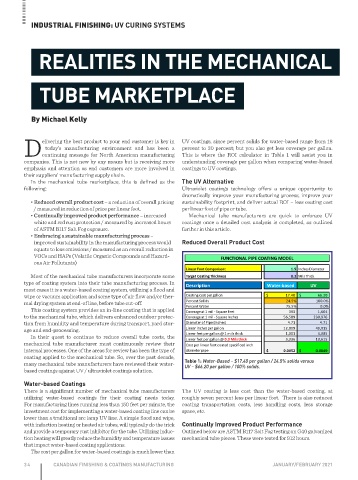

6543210/.-,2+2*0

Most of the mechanical tube manu facturers incorporate some ).(10'3.4&

type of coating system into their tube manufacturing process. In

most cases it is a water-based coating system, utilizing a flood and

0

0

wipe or vacuum application and some type of air flow and/or ther- %$-+.5#04$1+0"2*0#-(($5 000000000000000000000000 ! 00000000000000000000000

2*425+0 $(. 1 !

mal drying system at end-of line, before tube cut-off.

2*425+0 -+2*

This coating system provides an in-line coating that is applied %$ 2*-#20-+0!0,.(0 0 -*20 22+ 00000000000000000000000000000000 000000000000000000000000000 !

to the mechanical tube, which delivers enhanced outdoor protec- %$ 2*-#20-+0!0,.(0 0 -*20654321 0000000000000000000000000 000000000000000000000

tion from humidity and temperature during transport, yard stor- /.-,2+2*0$ 0 ."20 .54321 0000000000000000000000000000000 ! 000000000000000000000000000000 !

.52-*0.543210"2*0#-(($5 0000000000000000000000000 ! 000000000000000000000000 !

age and end-processing.

.52-*0 22+0"2*0#-(($50 0!0,.(10+3.4& 0000000000000000000000000000 ! ! 000000000000000000000000000

In their quest to continue to reduce overall tube costs, the .52-*0 22+0"2*0#-(($50 0 0000000000000000000000000000 000000000000000000000000 ! !

mechanical tube manufacturer must continuously review their %$1+0"2*0(.52-*0 $$+04$-+2 01"24. .42 0.5430

internal processes. One of the areas for review has been the type of .-,2+2*0"."2

coating applied to the mechanical tube. So, over the past decade,

Table 1: Water-Based – $17.40 per gallon / 24.5% solids versus

many mechanical tube manufacturers have reviewed their water-

UV – $66.20 per gallon / 100% solids.

based coatings against UV / ultraviolet coatings solution.

Water-based Coatings

There is a significant number of mechanical tube manufacturers The UV coating is less cost than the water-based coating, at

utilizing water-based coatings for their coating needs today. roughly seven percent less per linear foot. There is also reduced

For manufacturing lines running less than 150 feet per minute, the coating transportation costs, less handling costs, less storage

investment cost for implementing a water-based coating line can be space, etc.

lower than a traditional arc lamp UV line. A simple flood and wipe,

with induction heating or heated air tubes, will typically do the trick Continually Improved Product Performance

and provide a temporary rust inhibitor for the tube. Utilizing induc- Outlined below are ASTM B117 Salt Fog testing on G40 galvanized

tion heating will greatly reduce the humidity and temperature issues mechanical tube pieces. These were tested for 912 hours.

that impact water-based coating applications.

The cost per gallon for water-based coatings is much lower than

34 CANADIAN FINISHING & COATINGS MANUFACTURING JANUARY/FEBRUARY 2021