Page 20 - CFCM May-June 2021_Neat

P. 20

PLATING AND ANODIZING: ANODIZING PRETREATMENT

ALUMINUM ALCHEMY

By Connor Stewart

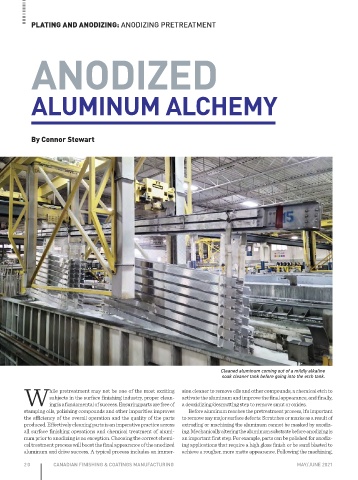

Cleaned aluminum coming out of a mildly alkaline

soak cleaner tank before going into the etch tank.

hile pretreatment may not be one of the most exciting sion cleaner to remove oils and other compounds, a chemical etch to

subjects in the surface finishing industry, proper clean- activate the aluminum and improve the final appearance, and finally,

Wing is a fundamental of success. Ensuring parts are free of a deoxidizing/desmutting step to remove smut or oxides.

stamping oils, polishing compounds and other impurities improves Before aluminum reaches the pretreatment process, it’s important

the efficiency of the overall operation and the quality of the parts to remove any major surface defects. Scratches or marks as a result of

produced. Effectively cleaning parts is an imperative practice across extruding or machining the aluminum cannot be masked by anodiz-

all surface finishing operations and chemical treatment of alumi- ing. Mechanically altering the aluminum substrate before anodizing is

num prior to anodizing is no exception. Choosing the correct chemi- an important first step. For example, parts can be polished for anodiz-

cal treatment process will boost the final appearance of the anodized ing applications that require a high gloss finish or be sand blasted to

aluminum and drive success. A typical process includes an immer- achieve a rougher, more matte appearance. Following the machining,

20 CANADIAN FINISHING & COATINGS MANUFACTURING MAY/JUNE 2021