Page 43 - The Inside Scoop Archive

P. 43

Page 1 of 3

Why does some stretch film come in COLORS ?

To: Inside Scoop Reader

Why are some stretch films colored and others are not. In the early days of stretch, the films made from

polyethylene were all clear. In those days PVC was also used for stretch film ( it would stretch 30% ) and

Bordens PVC had a yellow tint to it. In the late 70's when Mobil Chemical introduced the first LLDPE

stretch films, the decision was made to use colors to reinforce the Mobil X brand of film. The colors used

were blue for 120 gauge Mobil XH, green for 90 gauge Mobil X, and red for 70 gauge Mobil XL. The

branding was so successful that many competitors would try to copy the colors in their films to try and

identify their quality with that of Mobil. At one time there were several companies out selling green film.

It was confusing to the users as they would tell the distributor they were using green Mobil film, and they

would try to sell them another green film to replace it. Thank goodness those days are over.

Maybe it was because there were so many different colors of film in the marketplace at one time that some

buyers started wanting to color code and date their inventory by using different colors of stretch film.

Imagine your customer wanting to order one pallet each of 6 different colors. On top of that the colors

available for brand indentification were all different gauges. The stretch film producers moved away from

colors back to clear as extrusion rates increased and film came to be made at very high rates of speed.

With today's high speed production rates, the manufacturer has to run colors very sparingly and gang them

in periodic campaigns to run back to back. Once the color run is complete, they have to turn off the

extruder, and clean out the die, extruders, and blenders to remove any color pigment that might be hanging

around inside. As all shut downs are costly, this adds to the increased pricing for colored films. The color

pigments themselves can vary widely in price, with black being the cheapest, and some color masterbatches

costing as much as $ 0.18 per pound. Some manufacturers will accept 10,000 lb orders for colors and run

them once a month.

There are a couple of stretch film companies who run a lot of colors each month. One runs them in cast film

and the other in blown film. Two pallets of just about any color are available from either of these. Other

manufacturers will also run colors but with a lot more restrictions on order size and gauge. They are

produced in both hand wrap and machine film rolls.

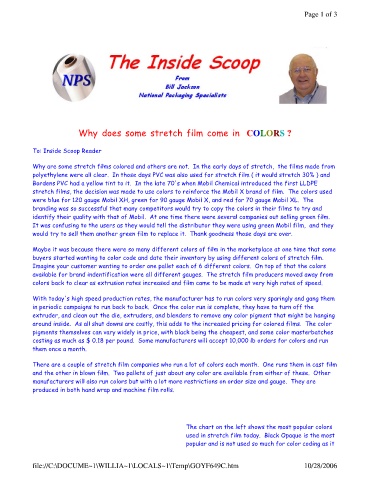

The chart on the left shows the most popular colors

used in stretch film today. Black Opaque is the most

popular and is not used so much for color coding as it

file://C:\DOCUME~1\WILLIA~1\LOCALS~1\Temp\GOYF649C.htm 10/28/2006