Page 4 - Drishti-Apr-Jun'24

P. 4

The Window to Our World

Volume : 01 (Apr’24-Jun’24)

Continuous

Improvement

PRITIKA GROUP OF INDUSTRIES

KAIZEN / IMPROVEMENT SHEET

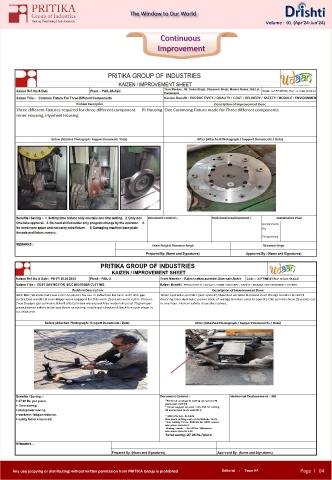

Kaizen Ref. No & Date :- PE 07/ 20.02.2024 Plant :- PAIL-2 Team Member :- Rajesh rattan,surinder,Som nath,Rohit Code :- IATFF/ME/05 Rev: A Date 19.02.21

Kaizen Title :- COST SAVING FOR IBCC BIG RISER CUTTING Kaizen Benefit : PRODUCTIVITY / QUALITY / COST / DELIVERY / SAFETY / MORALE / ENVIRONMENT / OTHERS

Problem Description Description of Improvement Done

IBCC BIG ( SG material ) was cut in to pieces for use in Induction Furnace with LPG gas Small hydraulic cylinder (jack system) Mounted on table & placed near Wedge breaker at Unit 1

cutter.One welder & one Helper were engaged for this work.25 pieces were cut in 8 hours. decoring area.Hydraulic power pack of wedge breaker used to operate this cylinder.Now 25 pieces cut

2nos Oxygen gas cylinders & half LPG Cylinder were used.Also material loss of 70 gram per in one hour. Human safety issue also solved.

piece.Human safety issue was there as cutting nozzle got chocked & back fire took place in

cutting torch.

Before (Attached Photograph / Support Documents / Data) After (Attached Photograph / Support Documents / Data)

Benefits / Saving :- Document Control :- Horizontal Deployement :- NIL

> 27.06 Rs. per piece. *Material wastage in cutting one piece=70

> Time saving. gram,cost-2,80 RS

> man power saving. * 01nos oxygen cyl,cost ==Rs 250 for cutting

50 pieces,One piece cost=Rs 5

> workmen fatigue reduced. * ONE LPG Cyl-- Rs 1576

> safety factor improved. One piece cutting cost=1576/100=Rs 15.76

*Gas cutting Torch--2000 Rs for 1000 pieces,

one piece cost=Rs 2

Cutting nozzle ---Rs 150 for 100 pieces

one piece cost=Rs 1.50

Total saving=27.06 Rs./piece

REMARKS :-

Prepared By: (Name and Signatures) Approved By : (Name and Signatures)

Any use (copying or distributing) without written permission from PRITIKA Group is prohibited Editorial : Team HR Page I 04