Page 96 - Hydra-matic 6 Speed RWD Technician's Guide (October 2005)

P. 96

68

(51)

ASSEMBLY

1-2-3-4 AND 3-5

REVERSE CLUTCH

➤

➤

➤

CLUTCH

APPLIED

3-5 REVERSE

(64)

3

2-6 AND

DRIVING

ASSEMBLY

3-5 REVERSE

CLUTCH HUB

APPLIED

REVERSE

(52)

INPUT

DRIVEN

CARRIER

➤

ASSEMBLY

➤

(53)

HELD

INPUT

SUN GEAR

(487)

➤

DRIVING

➤

OUTPUT CARRIER

FRONT SUN GEAR

6

(68)

INPUT

DRIVING

Figure 63

OUTPUT

CARRIER

ASSEMBLY

INTERNAL GEAR

➤

➤

(68)

➤

CARRIER

OUTPUT

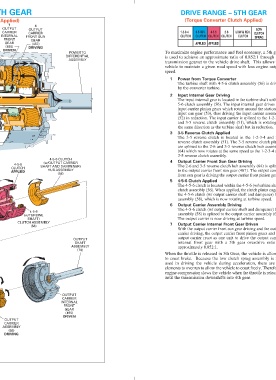

➤ ➤ ➤ ➤ ➤ ➤ DRIVEN (495) DRIVING GEAR DRIVING FRONT (1) APPLIED CLUTCH GEAR INTERNAL CONVERTER CLUTCH INTERNAL CARRIER TORQUE 4-5-6 3-5 INPUT OUTPUT POWER FROM 5 2 7 1 (T orque Converter Clutch Applied) DRIVE RANGE – 5TH GEAR

DRIVING

ASSEMBLY

4-5-6

CLUTCH

APPLIED

➤

➤ 1 speed. vehicle to maintain a given road speed with less engine output transmission gearset to the vehicle drive shaft. This allows the ASSEMBLY is used to achieve an approximate ratio of 0.852:1 through the DIFFERENTIAL POWER TO DRIVING (487) APPLIED GEAR SPRAG FRONT SUN CLUTCH CLUTCH CARRIER 1-2-3-4 OUTPUT 4 (Torque Converter Clutch Applied) DRIVE RANGE – 5TH GEAR

(56)

4-5-6

➤

SHAFT)

(w/TURBINE

CLUTCH ASSEMBLY

➤

(58)

4-5-6 CLUTCH

(495)

HUB ASSEMBLY

GEAR

FRONT

DRIVEN

OUTPUT

CARRIER

(w/OUTPUT CARRIER

INTERNAL

SHAFT AND DAMPENER)

(70)

SHAFT

OUTPUT

ASSEMBLY

2

3

4

7

5

6

3-5 REV.

CLUTCH

4-5-6

4-5-6 Clutch Applied

approximately 0.852:1.

CLUTCH

APPLIED

by the converter turbine.

3-5 reverse clutch assembly.

2-6

Input Internal Gear Driving

3-5 Reverse Clutch Applied

CLUTCH

Power from Torque Converter

Output Carrier Assembly Driving

CLUTCH

LOW & REV.

until the transmission downshifts into 4th gear.

Output Carrier Front Sun Gear Driving

Output Carrier Internal Front Gear Driven

LOW

The output carrier is now driving at turbine speed.

assembly (58), which is now rotating at turbine speed.

the same direction as the turbine shaft but in reduction.

The 3-5 reverse clutch is located in the 1-2-3-4 and 3-5

used in driving the vehicle during acceleration, there are no

and 3-5 reverse clutch assembly (51), which is rotating in

When the throttle is released in 5th Gear, the vehicle is allowed

to coast brake. Because the low clutch sprag assembly is not

(52) in reduction. The input carrier is splined to the 1-2-3-4

elements to overrun to allow the vehicle to coast freely. Therefore,

to the output carrier front sun gear (487). The output carrier

engine compression slows the vehicle when the throttle is released

The 2-6 and 3-5 reverse clutch hub assembly (64) is splined

front sun gear is driving the output carrier front pinion gears.

reverse clutch assembly (51). The 3-5 reverse clutch plates

are splined to the 2-6 and 3-5 reverse clutch hub assembly

(64) which now rotates at the same speed as the 1-2-3-4 and

The 4-5-6 clutch is located within the 4-5-6 (w/turbine shaft)

The input internal gear is located in the turbine shaft with 4-

The turbine shaft with 4-5-6 clutch assembly (56) is driven

clutch assembly (56). When applied, the clutch plates engage

The 4-5-6 clutch (w/ output carrier shaft and dampener) hub

assembly (58) is splined to the output carrier assembly (68).

the 4-5-6 clutch (w/ output carrier shaft and dampener) hub

With the output carrier front sun gear driving and the output

To maximize engine performance and fuel economy, a 5th gear

input carrier pinion gears which rotate around the stationary

input sun gear (53), thus driving the input carrier assembly

internal front gear with a 5th gear overdrive ratio of

5-6 clutch assembly (56). The input internal gear drives the

carrier driving, the output carrier front pinion gears and the

output carrier react as one unit to drive the output carrier

68A