Page 346 - Programmable Logic Controllers, Fifth Edition

P. 346

Figure 14-46 shows a smart belt packaging opera-

tion that uses a SERCOS module interface in conjunc-

tion with Allen-Bradley Kinetix 6000 multi-axis servo

drive. The operation of the process can be summarized

as follows:

Connectors • This packaging application is used to convert ran-

domly spaced product into evenly spaced product

that’s properly phased to the in-feed of another

machine.

Field

device • The SERCOS interface module is linked with fiber

Fieldbus

interface optic cable to the Allen-Bradley Kinetix 6000 servo

drive.

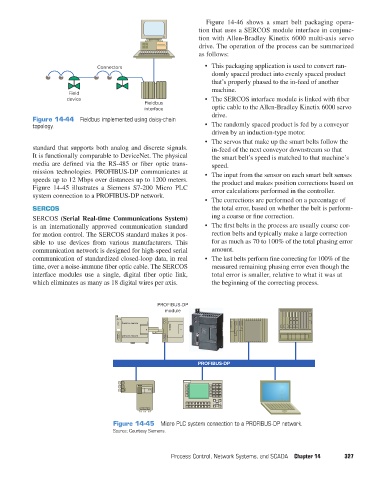

Figure 14-44 Fieldbus implemented using daisy-chain

topology. • The randomly spaced product is fed by a conveyor

driven by an induction-type motor.

• The servos that make up the smart belts follow the

standard that supports both analog and discrete signals. in-feed of the next conveyor downstream so that

It is functionally comparable to DeviceNet. The physical the smart belt’s speed is matched to that machine’s

media are defined via the RS-485 or fiber optic trans- speed.

mission technologies. PROFIBUS-DP communicates at • The input from the sensor on each smart belt senses

speeds up to 12 Mbps over distances up to 1200 meters. the product and makes position corrections based on

Figure 14-45 illustrates a Siemens S7-200 Micro PLC error calculations performed in the controller.

system connection to a PROFIBUS-DP network.

• The corrections are performed on a percentage of

SERCOS the total error, based on whether the belt is perform-

SERCOS (Serial Real-time Communications System) ing a coarse or fine correction.

is an internationally approved communication standard • The first belts in the process are usually coarse cor-

for motion control. The SERCOS standard makes it pos- rection belts and typically make a large correction

sible to use devices from various manufacturers. This for as much as 70 to 100% of the total phasing error

communication network is designed for high-speed serial amount.

communication of standardized closed-loop data, in real • The last belts perform fine correcting for 100% of the

time, over a noise-immune fiber optic cable. The SERCOS measured remaining phasing error even though the

interface modules use a single, digital fiber optic link, total error is smaller, relative to what it was at

which eliminates as many as 18 digital wires per axis. the beginning of the correcting process.

PROFIBUS-DP

module

PROFIBUS-DP

Figure 14-45 Micro PLC system connection to a PROFIBUS-DP network.

Source: Courtesy Siemens.

Process Control, Network Systems, and SCADA Chapter 14 327

pet73842_ch14_305-332.indd 327 05/11/15 4:29 PM