Page 487 - Mechatronics with Experiments

P. 487

Printer: Yet to Come

October 9, 2014 8:41 254mm×178mm

JWST499-Cetinkunt

JWST499-c07

ELECTROHYDRAULIC MOTION CONTROL SYSTEMS 473

Pre-compensator

valve

P

A 1 P

Adjustable s

orifice P

f b1

P s P s P Δ p ~ k spring

f b2

P

P f b1

f b1 Δ p P f b2 A 2

k spring P f b2

(a) (b) (c)

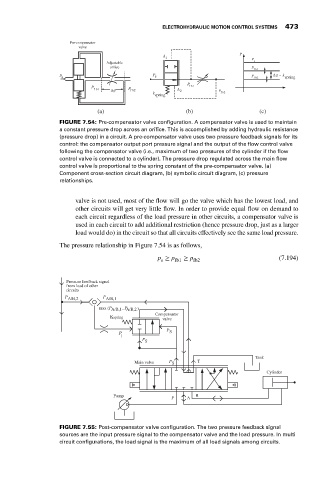

FIGURE 7.54: Pre-compensator valve configuration. A compensator valve is used to maintain

a constant pressure drop across an orifice. This is accomplished by adding hydraulic resistance

(pressure drop) in a circuit. A pre-compensator valve uses two pressure feedback signals for its

control: the compensator output port pressure signal and the output of the flow control valve

following the compensator valve (i.e., maximum of two pressures of the cylinder if the flow

control valve is connected to a cylinder). The pressure drop regulated across the main flow

control valve is proportional to the spring constant of the pre-compensator valve. (a)

Component cross-section circuit diagram, (b) symbolic circuit diagram, (c) pressure

relationships.

valve is not used, most of the flow will go the valve which has the lowest load, and

other circuits will get very little flow. In order to provide equal flow on demand to

each circuit regardless of the load pressure in other circuits, a compensator valve is

used in each circuit to add additional restriction (hence pressure drop, just as a larger

load would do) in the circuit so that all circuits effectively see the same load pressure.

The pressure relationship in Figure 7.54 is as follows,

p ≥ p fb1 ≥ p fb2 (7.194)

s

Pressure feedback signal

from load of other

circuits

P A/B,2 P A/B,1

max (P A/B,1 , P A/B,2 )

Compensator

Kspring valve

P

P S

l

P

S

Tank

Main valve P S T

Cylinder

Pump P A B

FIGURE 7.55: Post-compensator valve configuration. The two pressure feedback signal

sources are the input pressure signal to the compensator valve and the load pressure. In multi

circuit configurations, the load signal is the maximum of all load signals among circuits.