Page 78 - Michigan Drill

P. 78

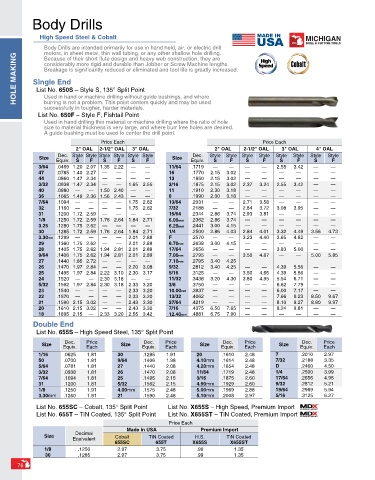

Body Drills

High Speed Steel & Cobalt

Body Drills are intended primarily for use in hand held, air, or electric drill

motors, in sheet metal, thin wall tubing, or any other shallow hole drilling.

HOLE MAKING Single End

Because of their short flute design and heavy web construction, they are

considerably more rigid and durable than Jobber or Screw Machine lengths.

Breakage is significantly reduced or eliminated and tool life is greatly increased.

List No. 650S – Style S, 135° Split Point

Used in hand or machine drilling without guide bushings, and where

burring is not a problem. This point centers quickly and may be used

successfully in tougher, harder materials.

List No. 650F – Style F, Fishtail Point

Used in hand drilling thin material or machine drilling where the ratio of hole

size to material thickness is very large, and where burr free holes are desired.

A guide bushing must be used to center the drill point.

Price Each Price Each

2" OAL 2-1/2" OAL 3" OAL 2" OAL 2-1/2" OAL 3" OAL 4" OAL

Dec. Style Style Style Style Style Style Dec. Style Style Style Style Style Style Style Style

Size Size

Equiv. S F S F S F Equiv. S F S F S F S F

3/64 .0469 1.20 2.07 1.35 2.22 — — 11/64 .1719 — — — — 2.55 3.42 — —

47 .0785 1.40 2.27 — — — — 16 .1770 2.15 3.02 — — — — — —

44 .0860 1.47 2.34 — — — — 13 .1850 2.15 3.02 — — — — — —

3/32 .0938 1.47 2.34 — — 1.65 2.55 3/16 .1875 2.15 3.02 2.37 3.24 2.55 3.42 — —

40 .0980 — — 1.50 2.40 — — 11 .1910 2.30 3.18 — — — — — —

36 .1065 1.49 2.36 1.56 2.43 — — 8 .1990 2.30 3.18 — — — — — —

7/64 .1094 — — — — 1.75 2.62 13/64 .2031 — — 2.71 3.58 — — — —

32 .1160 — — — — 1.75 2.62 7/32 .2188 — — 2.84 3.72 3.08 3.95 — —

31 .1200 1.72 2.59 — — — — 15/64 .2344 2.86 3.74 2.93 3.81 — — — —

1/8 .1250 1.72 2.59 1.76 2.64 1.84 2.71 6.00mm .2362 2.86 3.74 — — — — — —

3.25 .1280 1.75 2.62 — — — — 6.20mm .2441 3.00 4.15 — — — — — —

30 .1285 1.72 2.59 1.76 2.64 1.84 2.71 1/4 .2500 2.86 4.03 2.84 4.01 3.32 4.49 3.56 4.73

3.30mm .1299 — — — — 2.01 2.88 F .2570 — — 3.23 4.40 3.65 4.82 — —

29 .1360 1.75 2.62 — — 2.01 2.89 6.70mm .2638 3.00 4.15 — — — — — —

28 .1405 1.75 2.62 1.94 2.81 2.01 2.89 17/64 .2656 — — — — 3.83 5.00 — —

9/64 .1406 1.75 2.62 1.94 2.81 2.01 2.89 7.00mm .2795 — — 3.50 4.67 — — 5.00 5.85

27 .1440 1.85 2.72 — — — — 7.10mm .2795 3.40 4.25

26 .1470 1.97 2.84 — — 2.20 3.08 9/32 .2812 3.40 4.25 — — 4.39 5.56 — —

25 .1495 1.97 2.84 2.22 3.10 2.30 3.17 5/16 .3125 — — 3.50 4.65 4.39 5.56 — —

24 .1520 — — 2.30 3.18 — — 11/32 .3438 3.20 4.30 3.80 4.95 5.54 6.71 — —

5/32 .1562 1.97 2.84 2.30 3.18 2.33 3.20 3/8 .3750 — — — — 6.62 7.79 — —

23 .1540 — — — — 2.33 3.20 10.00mm .3937 — — — — 6.00 7.17 — —

22 .1570 — — — — 2.33 3.20 13/32 .4062 — — — — 7.66 9.23 8.50 9.67

21 .1590 2.15 3.02 — — 2.43 3.30 27/64 .4219 — — — — 8.10 9.27 8.80 9.97

20 .1610 2.15 3.02 — — 2.43 3.30 7/16 .4375 6.50 7.65 — — 8.24 9.81 — —

18 .1695 2.15 — 2.33 3.20 2.55 3.42 12.40mm .4881 6.75 7.90 — — — — — —

Double End

List No. 655S – High Speed Steel, 135° Split Point

Dec.

Dec.

Dec.

Dec.

Size Equiv. Price Size Equiv. Price Size Equiv. Price Size Equiv. Price

Each

Each

Each

Each

1/16 .0625 1.81 30 .1285 1.91 20 .1610 2.48 7 .2010 2.97

50 .0700 1.81 9/64 .1406 1.98 4.10mm .1614 2.48 7/32 .2188 3.35

5/64 .0781 1.81 27 .1440 2.08 4.20mm .1654 2.48 D .2460 4.50

3/32 .0938 1.81 26 .1470 2.08 11/64 .1719 2.48 1/4 .2500 3.99

7/64 .1094 1.81 25 .1495 2.15 3/16 .1875 2.60 17/64 .2656 4.95

31 .1200 1.81 5/32 .1562 2.15 4.90mm .1929 2.60 9/32 .2812 5.21

1/8 .1250 1.91 4.00mm .1575 2.48 5.00mm .1969 2.88 19/64 .2969 5.94

3.30mm .1260 1.91 21 .1590 2.48 5.10mm .2008 2.97 5/16 .3125 6.27

List No. 655SC – Cobalt, 135° Split Point List No. X655S – High Speed, Premium Import

List No. 655T – TiN Coated, 135° Split Point List No. X655ST – TiN Coated, Premium Import

Price Each

Made in USA Premium Import

Decimal

Size Cobalt TiN Coated H.S. TiN Coated

Equivalent

655SC 655T X655S X655ST

1/8 .1250 2.97 3.75 .99 1.35

30 .1285 2.97 3.75 .99 1.35

76