Page 5 - LAS 800 – versatile and flexible fume extraction

P. 5

190 Seite 4

210 Seite 2

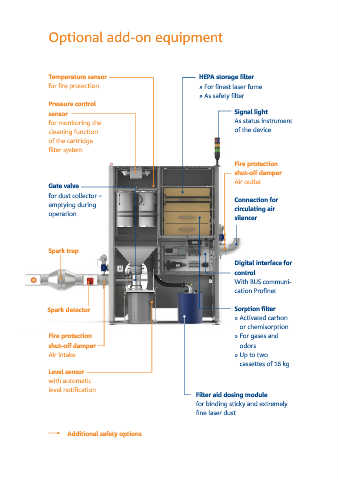

To everyone who produces laser fume Basic equipment 210 Seite 3 Optional add-on equipment

Extremely fine laser dust is an unwanted production stops, filter exchanges, or Cleaning system Temperature sensor HEPA storage filter

waste product in laser material processing providing additional technology. For filter cartridges for fire protection » For finest laser fume

– potentially dangerous to human health, That costs time, space, and money. with compressed » As safety filter

machine functionality and product quality. Consequently, laser fume extraction may air tank and valves Pressure control

Therefore, utilizing fume extraction become the Achilles‘ heel of production. sensor Signal light

technology is not only indispensable but ULT presents extraction technology, for monitoring the As status instrument

also challenging in daily production specifically developed for laser processing Space for optional cleaning function of the device

practice. Influential parameters can be the of ever-changing materials in /

. filter modules of the cartridge

amount of produced dust or the very The LAS combines ULT’s long-term Cartridge filter (complementary filter system

different dust compositions − depending experience in laser fume extraction in a pieces of . m storage filters) Fire protection

on which materials are currently being versatile and powerful premium product. filter surface shut-off damper

processed. In practice this means repeated Air outlet

Digital control, control Gate valve

panel and display for dust collector − Connection for

» With operating emptying during circulating air

Hopper status and error operation

Air pollutants and filter types in laser material processing silencer

with copper baffle display

plate for direct » Multilingual,

Gases / odors Laser fume Laser dust separation of switchable

coarse particles » Analog interface Spark trap

. µm . µm . µm . µm µm and to prevent

µm Digital interface for

Particle size impact sparks control

Cartridge filter Energy efficient high- With BUS communi-

pressure ventilator

HEPA storage filter » Extremely quiet in cation Profinet

operation

Sorption filter Spark detector Sorption filter

Dust collector » Adjustable suction

(activated carbon / chemisorption) l power » Activated carbon

or chemisorption

Fire protection » For gases and

shut-off damper odors

Typical applications for LAS Air intake » Up to two

cassettes of kg

Processing types: Industries including: The additional equipment in the LAS was To counter the increased risk of fire and Level sensor

» Laser cutting » Plastics processing designed for complex air pollutant situations, explosion in connection with the laser with automatic

» Laser sintering » Machinery caused by changing materials and production processing of certain metals, additional level notification

» Laser welding » Electronics manufacturing conditions. Sticky laser dusts and extremely safety options are offered. For the integration Filter aid dosing module

» Laser marking » Automotive fine laser fume may occur, often accompanied into automated production, the LAS for binding sticky and extremely

» Laser structuring » Aerospace by toxic gases and unpleasant odors. optionally provides a network connection fine laser dust

» Laser ablation » Advertising material production Additional filters are required to separate to the digital control of the entire system.

these air pollutants. Additional safety options

ULT-LAS800-EN-2021.indd 2 Format [mm]: 610 x 297 (offen); 210 x 297 (geschlossen) Farben: Cyan Magenta Gelb Schwarz 02.02.21 11:53