Page 418 - Icon Ridge Maintenance & Service Catalog

P. 418

Drilling, Milling, Tapping and Threading

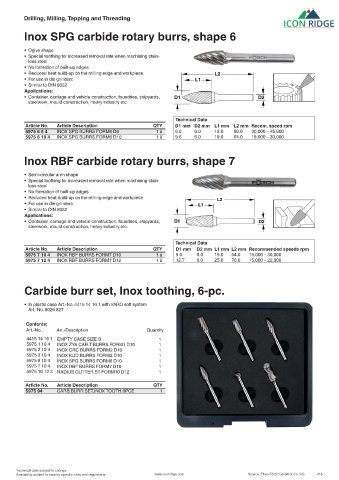

Inox SPG carbide rotary burrs, shape 6

• Ogive shape

• Special toothing for increased removal rate when machining stain-

less steel

• No formation of built-up edges

• Reduced heat build-up on the milling edge and workpiece

• For use in die grinders

• Similar to DIN 8032

Applications:

• Container, carriage and vehicle construction, foundries, shipyards,

steelwork, mould construction, heavy industry etc.

Technical Data

Article No. Article Description QTY D1 mm D2 mm L1 mm L2 mm Recom. speed rpm

5975 6 6 4 INOX SPG BURRS FORM6 D6 1 ü 6.0 6.0 18.0 50.0 30,000 – 45,000

5975 6 10 4 INOX SPG BURRS FORM6 D10 1 ü 9.6 6.0 19.0 64.0 19,000 – 30,000

Inox RBF carbide rotary burrs, shape 7

• Semi-circular arch shape

• Special toothing for increased removal rate when machining stain-

less steel

• No formation of built-up edges

• Reduced heat build-up on the milling edge and workpiece

• For use in die grinders

• Similar to DIN 8032

Applications:

• Container, carriage and vehicle construction, foundries, shipyards,

steelwork, mould construction, heavy industry etc.

Technical Data

Article No. Article Description QTY D1 mm D2 mm L1 mm L2 mm Recommended speeds rpm

5975 7 10 4 INOX RBF BURRS FORM7 D10 1 ü 9.6 6.0 19.0 64.0 19,000 – 30,000

5975 7 12 4 INOX RBF BURRS FORM7 D12 1 ü 12.7 6.0 25.0 70.0 15,000 – 22,000

Carbide burr set, Inox toothing, 6-pc.

• In plastic case Art.-No. 4415 14 16 1 with VARO soft system

Art.-No. 9026 827

Contents:

Art.-No.. Art.-Description Quantity

4415 14 16 1 EMPTY CASE SIZE B 1

5975 1 10 4 INOX ZYA CAR.T.BURRS FORM1 D10 1

5975 2 10 4 INOX CRC BURRS FORM2 D10 1

5975 3 10 4 INOX KUD BURRS FORM3 D10 1

5975 6 10 4 INOX SPG BURRS FORM6 D10 1

5975 7 10 4 INOX RBF BURRS FORM7 D10 1

5975 10 12 3 RADIUS CUTTER ST FORM10 D12 1

Article No. Article Description QTY

5975 94 CARB.BURR SET,INOX TOOTH.6PCE 1

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 418