Page 115 - Icon Ridge Presents ORION

P. 115

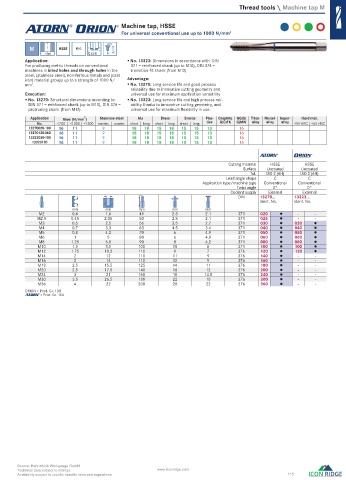

Thread tools \ Machine tap M

Machine tap, HSSE

For universal conventional use up to 1000 N/mm 2

conv.

M HSSE

3xd C (2-3)

Application: No. 13323: Dimensions in accordance with: DIN

For producing metric threads on conventional 371 = reinforced shank (up to M10), DIN 376 =

machines in blind holes and through holes in the transition-fi t shank (from M12)

steel, (stainless steel), non-ferrous metals and (cast

iron) material groups up to a strength of 1000 N/ Advantage:

mm . 2 No. 13270: Long service life and good process

reliability due to innovative cutting geometry and

Execution: universal use for maximum application versatility

No. 13270: Structural dimensions according to: No. 13323: Long service life and high process reli-

DIN 371 = reinforced shank (up to M10), DIN 376 = ability thanks to innovative cutting geometry, and

protruding shank (from M12) universal use for maximum fl exibility in use.

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13270020-100 16 11 9 18 18 15 18 15 15 13 16

13270120-360 16 11 9 18 18 15 18 15 15 13 16

13323030-100 16 11 9 18 18 15 18 15 15 13 16

13323120 16 11 9 18 18 15 18 15 15 13 16

Cutting material HSSE HSSE

Surface Uncoated Uncoated

Tol. ISO 2 (6H) ISO 2 (6H)

Lead angle shape C C

Application type/machine type Conventional Conventional

Twist angle 0° 0°

Coolant supply External External

DIN 13270... 13323...

Ident. No. Ident. No.

mm mm mm mm mm

M2 0.4 1.6 45 2.8 2.1 371 020 - -

M2.5 0.45 2.05 50 2.8 2.1 371 025 - -

M3 0.5 2.5 56 3.5 2.7 371 030 030

M4 0.7 3.3 63 4.5 3.4 371 040 040

M5 0.8 4.2 70 6 4.9 371 050 050

M6 1 5 80 6 4.9 371 060 060

M8 1.25 6.8 90 8 6.2 371 080 080

M10 1.5 8.5 100 10 8 371 100 100

M12 1.75 10.2 110 9 7 376 120 120

M14 2 12 110 11 9 376 140 - -

M16 2 14 110 12 9 376 160 - -

M18 2.5 15.5 125 14 11 376 180 - -

M20 2.5 17.5 140 16 12 376 200 - -

M24 3 21 160 18 14.5 376 240 - -

M30 3.5 26.5 180 22 18 376 300 - -

M36 4 32 200 28 22 376 360 - -

ORION = Prod. Gr. 1DB

a = Prod. Gr. 1KA

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 115

0211_EN_2018_KERN[21847008]-n.indd 213 12/17/2018 3:31:52 PM