Page 198 - Icon Ridge Presents ORION

P. 198

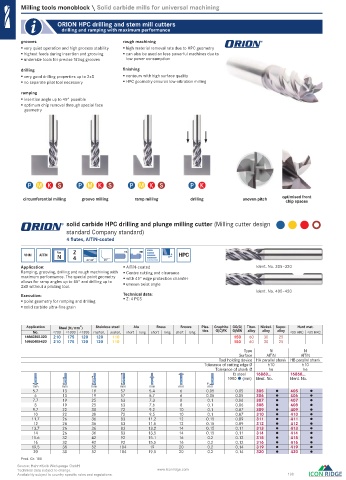

Milling tools monoblock \ Solid carbide mills for universal machining

ORION HPC drilling and stem mill cutters

drilling and ramping with maximum performance

grooves rough machining

very quiet operation and high process stability high material removal rate due to HPC geometry

highest feeds during insertion and grooving can also be used on less powerful machines due to

undersize tools for precise fi tting grooves low power consumption

drilling fi nishing

very good drilling properties up to 2xD contours with high surface quality

no separate pilot tool necessary HPC geometry ensures low-vibration milling

ramping

insertion angle up to 45° possible

optimum chip removal through special face

geometry

circumferential milling groove milling ramp milling drilling uneven pitch optimised front

chip spaces

solid carbide HPC drilling and plunge milling cutter ( Milling cutter design

standard Company standard )

4 flutes, AlTiN-coated

Typ Z HA HB

VHM AlTiN N 4 35°/38° 45° HPC

Application: AlTiN-coated Ident. No. 305–320

Ramping, grooving, drilling and rough machining with Centre cutting and clearance

maximum performance. The special point geometry with 45° edge protection chamfer

allows for ramp angles up to 45° and drilling up to

2xD without a piloting tool. uneven twist angle

Execution: Technical data: Ident. No. 405–420

point geometry for ramping and drilling Z: 4 PCS

solid carbide ultra-fi ne grain

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16860305-320 210 175 120 120 110 150 60 30 25

16860405-420 210 175 120 120 110 150 60 30 25

Type N N

Surface AlTiN AlTiN

Tool holding device HA parallel shank HB parallel shank

Tolerance of cutting edge Ø h10 h10

Tolerance of shank Ø h6 h6

fz steel 16860... 16860...

1000 (mm) Ident. No. Ident. No.

mm mm mm mm mm mm mm

5.7 13 19 57 5.4 6 0.05 0.05 305 405

6 13 19 57 5.7 6 0.05 0.05 306 406

7.7 19 25 63 7.3 8 0.1 0.06 307 407

8 19 25 63 7.6 8 0.1 0.06 308 408

9.7 22 30 72 9.2 10 0.1 0.07 309 409

10 22 30 72 9.5 10 0.1 0.07 310 410

11.7 26 36 83 11.2 12 0.15 0.09 311 411

12 26 36 83 11.5 12 0.15 0.09 312 412

13.7 26 36 83 13.2 14 0.15 0.11 313 413

14 26 36 83 13.5 14 0.15 0.11 314 414

15.6 32 42 92 15.1 16 0.2 0.12 315 415

16 32 42 92 15.5 16 0.2 0.12 316 416

19.5 38 52 104 19 20 0.2 0.14 319 419

20 38 52 104 19.5 20 0.2 0.14 320 420

Prod. Gr. 150

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 198

0370_EN_2018_KERN[21847607]-o.indd 370 12/17/2018 3:32:21 PM