Page 25 - Icon Ridge Presents ORION

P. 25

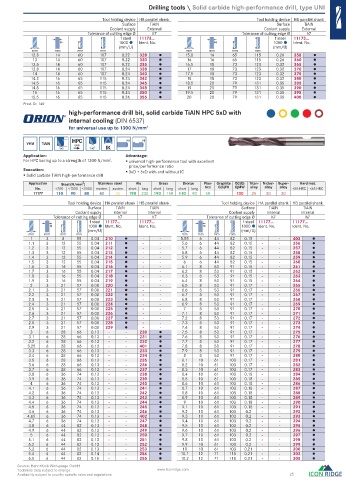

Drilling tools \ Solid carbide high-performance drill, type UNI

Tool holding device HB parallel shank Tool holding device HB parallel shank

Surface TiAlN Surface TiAlN

Coolant supply External Coolant supply External

Tolerance of cutting edge Ø h7 Tolerance of cutting edge Ø h7

f steel 11173... f steel 11173...

h6 1000 Ident. No. h6 1000 Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm mm mm

12.8 14 60 107 0.22 328 15.8 16 65 115 0.26 358

13 14 60 107 0.22 330 16 16 65 115 0.26 360

13.5 14 60 107 0.22 335 16.5 18 73 123 0.32 365

13.8 14 60 107 0.24 338 17 18 73 123 0.32 370

14 14 60 107 0.24 340 17.5 18 73 123 0.32 375

14.2 16 65 115 0.24 342 18 18 73 123 0.32 380

14.5 16 65 115 0.24 345 18.5 20 79 131 0.35 385

14.8 16 65 115 0.24 348 19 20 79 131 0.35 390

15 16 65 115 0.24 350 19.5 20 79 131 0.35 395

15.5 16 65 115 0.26 355 20 20 79 131 0.35 400

Prod. Gr. 140

high-performance drill bit, solid carbide TiAlN HPC 5xD with

internal cooling ( DIN 6537 )

for universal use up to 1300 N/mm 2

HPC HA HB

VHM TiAlN UNI

5xD 140° IK

Application: Advantage:

For HPC boring up to a strength of 1300 N/mm . 2 universal high-performance tool with excellent

price/performance ratio

Execution: 3xD + 5xD with and without IC

Solid carbide TiAlN high-performance drill

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11177 110 90 80 40 35 190 230 190 150 110 90 50 100 35 30 30

Tool holding device HA parallel shank HB parallel shank Tool holding device HA parallel shank HB parallel shank

Surface TiAlN TiAlN Surface TiAlN TiAlN

Coolant supply Internal Internal Coolant supply Internal Internal

Tolerance of cutting edge Ø h7 h7 Tolerance of cutting edge Ø h7 h7

f steel 11177... 11177... f steel 11177... 11177...

h6 1000 Ident. No. Ident. No. h6 1000 Ident. No. Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm mm mm

1 3 8 55 0.04 210 - - 5.55 6 44 82 0.15 - - 403

1.1 3 12 55 0.04 211 - - 5.6 6 44 82 0.15 - - 256

1.2 3 12 55 0.04 212 - - 5.7 6 44 82 0.15 - - 257

1.3 3 12 55 0.04 213 - - 5.8 6 44 82 0.15 - - 258

1.4 3 12 55 0.04 214 - - 5.9 6 44 82 0.15 - - 259

1.5 3 12 55 0.04 215 - - 6 6 44 82 0.15 - - 260

1.6 3 16 55 0.04 216 - - 6.1 8 53 91 0.15 - - 261

1.7 3 16 55 0.04 217 - - 6.2 8 53 91 0.15 - - 262

1.8 3 16 55 0.04 218 - - 6.3 8 53 91 0.15 - - 263

1.9 3 16 55 0.04 219 - - 6.4 8 53 91 0.15 - - 264

2 3 21 57 0.08 220 - - 6.5 8 53 91 0.17 - - 265

2.1 3 21 57 0.08 221 - - 6.6 8 53 91 0.17 - - 266

2.2 3 21 57 0.08 222 - - 6.7 8 53 91 0.17 - - 267

2.3 3 21 57 0.08 223 - - 6.8 8 53 91 0.17 - - 268

2.4 3 21 57 0.08 224 - - 6.9 8 53 91 0.17 - - 269

2.5 3 21 57 0.08 225 - - 7 8 53 91 0.17 - - 270

2.6 3 21 57 0.08 226 - - 7.1 8 53 91 0.17 - - 271

2.7 3 21 57 0.08 227 - - 7.2 8 53 91 0.17 - - 272

2.8 3 21 57 0.08 228 - - 7.3 8 53 91 0.17 - - 273

2.9 3 21 57 0.08 229 - - 7.4 8 53 91 0.17 - - 274

3 6 28 66 0.13 - - 230 7.5 8 53 91 0.17 - - 275

3.1 6 28 66 0.13 - - 231 7.6 8 53 91 0.17 - - 276

3.2 6 28 66 0.13 - - 232 7.7 8 53 91 0.17 - - 277

3.25 6 28 66 0.13 - - 401 7.8 8 53 91 0.17 - - 278

3.3 6 28 66 0.13 - - 233 7.9 8 53 91 0.17 - - 279

3.4 6 28 66 0.13 - - 234 8 8 53 91 0.17 - - 280

3.5 6 28 66 0.13 - - 235 8.1 10 61 103 0.17 - - 281

3.6 6 28 66 0.13 - - 236 8.2 10 61 103 0.17 - - 282

3.7 6 28 66 0.13 - - 237 8.3 10 61 103 0.17 - - 283

3.8 6 36 74 0.13 - - 238 8.4 10 61 103 0.18 - - 284

3.9 6 36 74 0.13 - - 239 8.5 10 61 103 0.18 - - 285

4 6 36 74 0.13 - - 240 8.6 10 61 103 0.18 - - 286

4.1 6 36 74 0.13 - - 241 8.7 10 61 103 0.18 - - 287

4.2 6 36 74 0.13 - - 242 8.8 10 61 103 0.18 - - 288

4.3 6 36 74 0.13 - - 243 8.9 10 61 103 0.18 - - 289

4.4 6 36 74 0.13 - - 244 9 10 61 103 0.18 - - 290

4.5 6 36 74 0.13 - - 245 9.1 10 61 103 0.18 - - 291

4.6 6 36 74 0.13 - - 246 9.2 10 61 103 0.2 - - 292

4.65 6 36 74 0.13 - - 402 9.3 10 61 103 0.2 - - 293

4.7 6 36 74 0.13 - - 247 9.4 10 61 103 0.2 - - 294

4.8 6 44 82 0.13 - - 248 9.5 10 61 103 0.2 - - 295

4.9 6 44 82 0.13 - - 249 9.6 10 61 103 0.2 - - 296

5 6 44 82 0.13 - - 250 9.7 10 61 103 0.2 - - 297

5.1 6 44 82 0.13 - - 251 9.8 10 61 103 0.2 - - 298

5.2 6 44 82 0.13 - - 252 9.9 10 61 103 0.2 - - 299

5.3 6 44 82 0.13 - - 253 10 10 61 103 0.21 - - 300

5.4 6 44 82 0.14 - - 254 10.1 12 71 118 0.21 - - 303

5.5 6 44 82 0.15 - - 255 10.2 12 71 118 0.21 - - 305

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 25

0028_EN_2018_KERN[21841686]-h.indd 33 12/17/2018 3:31:23 PM