Page 316 - Icon Ridge Presents ORION

P. 316

Turning tools \ Parting tools

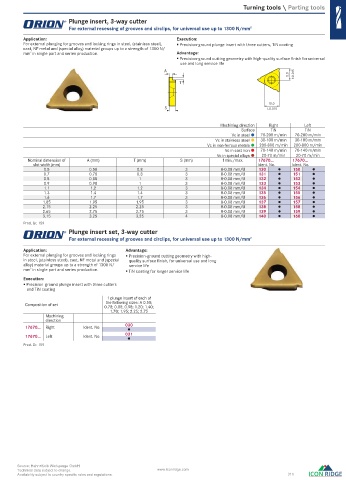

Plunge insert, 3-way cutter

For external recessing of grooves and circlips, for universal use up to 1300 N/mm 2

Application: Execution:

For external plunging for grooves and locking rings in steel, (stainless steel), Precision-ground plunge insert with three cutters, TiN coating

cast, NF metal and (special alloy) material groups up to a strength of 1300 N/

mm in single part and series production. Advantage:

2

Precision-ground cutting geometry with high-quality surface fi nish for universal

use and long service life

A

8.0 + 0.015

T -

10.0

S + - 0.015

Machining direction Right Le

Surface TiN TiN

Vc in steel 70-200 m/min 70-200 m/min

Vc in stainless steel 30-100 m/min 30-100 m/min

Vc in non-ferrous metals 200-800 m/min 200-800 m/min

Vc in cast iron 70-140 m/min 70-140 m/min

Vc in special alloys 20-70 m/min 20-70 m/min

Nominal dimension of A (mm) T (mm) S (mm) f min./max. 17670... 17670...

slot width (mm) Ident. No. Ident. No.

0.5 0.58 0.8 3 0-0.08 mm/U 130 150

0.7 0.78 0.8 3 0-0.08 mm/U 131 151

0.8 0.88 1 3 0-0.08 mm/U 132 152

0.9 0.98 1 3 0-0.08 mm/U 133 153

1.1 1.2 1.2 3 0-0.08 mm/U 134 154

1.3 1.4 1.4 3 0-0.08 mm/U 135 155

1.6 1.7 1.7 3 0-0.08 mm/U 136 156

1.85 1.95 1.95 3 0-0.08 mm/U 137 157

2.15 2.25 2.25 3 0-0.08 mm/U 138 158

2.65 2.75 2.75 3 0-0.08 mm/U 139 159

3.15 3.25 3.25 4 0-0.08 mm/U 140 160

Prod. Gr. 159

Plunge insert set, 3-way cutter

For external recessing of grooves and circlips, for universal use up to 1300 N/mm 2

Application: Advantage:

For external plunging for grooves and locking rings Precision-ground cutting geometry with high-

in steel, (stainless steel), cast, NF metal and (special quality surface fi nish, for universal use and long

alloy) material groups up to a strength of 1300 N/ service life

mm in single part and series production. TiN coating for longer service life

2

Execution:

Precision-ground plunge insert with three cutters

and TiN coating

1 plunge insert of each of

the following sizes: A 0.58;

Composition of set 0.78; 0.88; 0.98; 1.20; 1.40;

1.70; 1.95; 2.25; 2.75

Machining

direction

17670... Right Ident. No. 030

17670... Le Ident. No. 031

Prod. Gr. 159

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 316

0680_EN_2018_KERN[21848028]-l.indd 683 12/17/2018 3:34:03 PM