Page 377 - Icon Ridge Presents ORION

P. 377

Workpiece clamping \ Technical introduction – lathe chucks

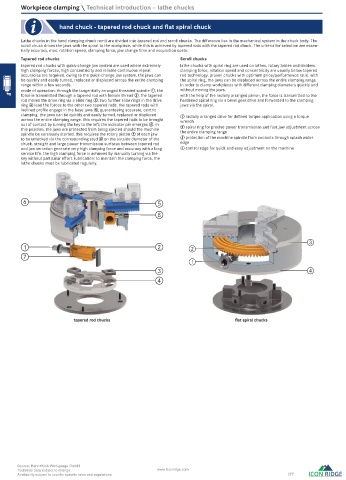

hand chuck - tapered rod chuck and flat spiral chuck

Lathe chucks in the hand clamping chuck remit are divided into tapered rod and scroll chucks. The difference lies in the mechanical system in the chuck body. The

scroll chuck drives the jaws with the spiral to the workpiece, while this is achieved by tapered rods with the tapered rod chuck. The criteria for selection are essen-

tially accuracy, max. rotation speed, clamping force, jaw change time and acquisition costs.

Tapered rod chucks Scroll chucks

tapered rod chucks with quick-change jaw system are used where extremely lathe chucks with spiral ring are used on lathes, rotary tables and dividers.

high clamping forces, high concentricity and reliable continuous repeat clamping force, rotation speed and concentricity are usually below tapered

accuracies are required. owing to the quick-change jaw system, the jaws can rod technology. proven chucks with optimum price/performance ratio. with

be quickly and easily turned, replaced or displaced across the entire clamping the spiral ring, the jaws can be displaced across the entire clamping range

range within a few seconds. in order to clamp workpieces with different clamping diameters quickly and

mode of operation: through the tangentially arranged threaded spindle ①, the without moving the jaws.

force is transmitted through a tapered rod with female thread ②. the tapered with the help of the radially arranged pinion, the force is transmitted to the

rod moves the drive ring via a slide ring ③. two further slide rings in the drive hardened spiral ring via a bevel gear drive and forwarded to the clamping

ring ④ lead the forces to the other two tapered rods. the tapered rods with jaws via the spiral.

inclined profi le engage in the base jaws ⑤, guaranteeing accurate, centric

clamping. the jaws can be quickly and easily turned, replaced or displaced ① radially arranged drive for defi ned torque application using a torque

across the entire clamping range. this requires the tapered rods to be brought wrench

out of contact by turning the key to the le�; the indicator pin emerges ⑥. in

this position, the jaws are protected from being ejected should the machine ② spiral ring for precise power transmission and fast jaw adjustment across

spindle be carelessly started. this requires the rotary piston ⑦ of each jaw the entire clamping range

to be unlocked via the corresponding stud ⑧ on the outside diameter of the ③ protection of the machine spindle from coolants through splash water

chuck. straight and large power transmission surfaces between tapered rod edge

and jaw serration generate very high clamping force and accuracy with a long ④ control edge for quick and easy adjustment on the machine

service life. the high clamping force is achieved by manually turning via the

key without particular effort. lubrication: to maintain the clamping force, the

lathe chucks must be lubricated regularly.

6 5

8

3

1 2 2

7

1

3 4

4

tapered rod chucks flat spiral chucks

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 377

0842_EN_2018_KERN[21850062]-o.indd 842 12/17/2018 3:34:02 PM