Page 80 - Icon Ridge Presents ORION

P. 80

Reaming tools \ Technical introduction – reaming

The basics of reaming

reaming is part of the precision machining process or fi nishing process. holes are mainly reamed in case of

special requirements around surface quality, roundness, cylindricity and diameter tolerance.

set the hole with a particular allowance, see allowance table, then create the desired fi t with the reamer.

Note: if not necessary, do not countersink hole due to the negative impact on the service life of the reamer.

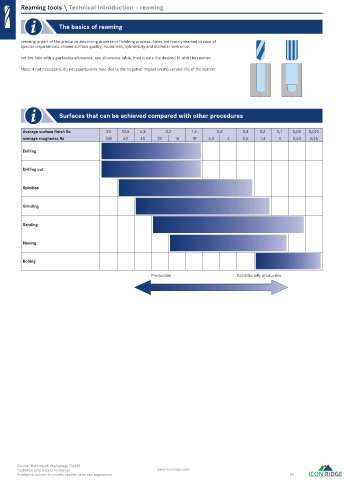

Surfaces that can be achieved compared with other procedures

Average surface finish Ra 25 12,5 6,3 3,2 1,6 0,8 0,4 0,2 0,1 0,05 0,025

average roughness Rz 100 63 40 25 16 10 6,3 4 2,5 1,6 1 0,63 0,25

Drilling

Drilling out

Spindles

Grinding

Sanding

Honing

Rolling

Producible Conditionally producible

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 80

0156_EN_2018_KERN[21846859]-k.indd 156 12/17/2018 3:30:57 PM