Page 119 - 2019 LRF Catalog_FULL_Spread

P. 119

HOMEMADE SOAP

COLD PROCESS SOAP

Cold process soap making is the method most often used by soap makers who make soap

from scratch. It's called "cold" process because no additional heat is added during the soap

making process, however the process itself does

generate heat. Soaps produced via the cold process method are opaque and usually have a

creamy feel to the bar. Without any additives that change the color, the soap ranges from

white-white to creamy-tan, depending on the oils used in making the soap.

Cold process soaps will continue to get harder as they age because additional water

evaporates out of the soap.

HOT PROCESS SOAP

Hot process soap making, uses additional heat in the soap making process. The chemical

reaction is the same but occurs faster than in cold process soap making.

Because of the additional heat, the finished soap bar tends to feel smoother to the touch.

The hardness of the bar again depends on the selection of oils, amount of water used in the

process and length of time allowed for water to evaporate out of the finished bar.

Hot process soap is opaque and ranges from white-white to creamy-tan depending on the

oils used, although clear soaps can be produced.

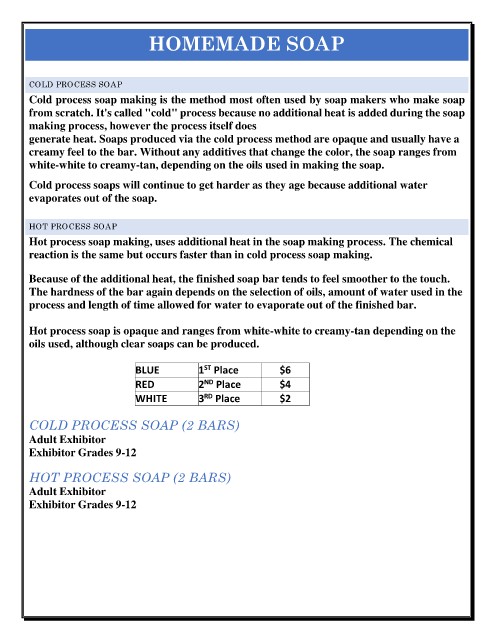

BLUE 1ST Place $6

RED 2ND Place $4

WHITE 3RD Place $2

COLD PROCESS SOAP (2 BARS)

Adult Exhibitor

Exhibitor Grades 9-12

HOT PROCESS SOAP (2 BARS)

Adult Exhibitor

Exhibitor Grades 9-12