Page 25 - CIMA MCS Workbook November 2018 - Day 2 Tasks

P. 25

ADVANCED FINANCIAL REPORTING (F2) ‐ PRACTICE TASKS

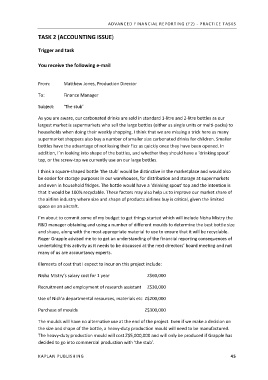

TASK 2 (ACCOUNTING ISSUE)

Trigger and task

You receive the following e‐mail

From: Matthew Jones, Production Director

To: Finance Manager

Subject: ‘The stub’

As you are aware, our carbonated drinks are sold in standard 1‐litre and 2‐litre bottles as our

largest market is supermarkets who sell the large bottles (either as single units or multi‐packs) to

households when doing their weekly shopping. I think that we are missing a trick here as many

supermarket shoppers also buy a number of smaller size carbonated drinks for children. Smaller

bottles have the advantage of not losing their fizz as quickly once they have been opened. In

addition, I’m looking into shape of the bottles, and whether they should have a ‘drinking spout’

top, or the screw‐top we currently use on our large bottles.

I think a square‐shaped bottle ‘the stub’ would be distinctive in the marketplace and would also

be easier for storage purposes in our warehouses, for distribution and storage at supermarkets

and even in household fridges. The bottle would have a ‘drinking spout’ top and the intention is

that it would be 100% recyclable. These factors may also help us to improve our market share of

the airline industry where size and shape of products airlines buy is critical, given the limited

space on an aircraft.

I’m about to commit some of my budget to get things started which will include Nisha Mistry the

R&D manager obtaining and using a number of different moulds to determine the best bottle size

and shape, along with the most appropriate material to use to ensure that it will be recyclable.

Roger Grapple advised me to to get an understanding of the financial reporting consequences of

undertaking this activity as it needs to be discussed at the next directors’ board meeting and not

many of us are accountancy experts.

Elements of cost that I expect to incur on this project include:

Nisha Mistry’s salary cost for 1 year Z$60,000

Recruitment and employment of research assistant Z$30,000

Use of Nish’a departmental resources, materials etc Z$200,000

Purchase of moulds Z$300,000

The moulds will have no alternative use at the end of the project. Even if we make a decision on

the size and shape of the bottle, a heavy‐duty production mould will need to be manufactured.

The heavy‐duty production mould will cost Z$5,000,000 and will only be produced if Grapple has

decided to go into commercial production with ‘the stub’.

KAPLAN PUBLISHING 45