Page 20 - 3DA Mag N° February2018 -EN+

P. 20

CASE STUDY

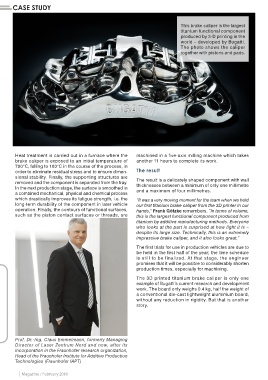

This brake caliper is the largest

titanium functional component

produced by 3-D printing in the

world – developed by Bugatti.

The photo shows the caliper

together with pistons and pads.

Heat treatment is carried out in a furnace where the machined in a five-axis milling machine which takes

brake caliper is exposed to an initial temperature of another 11 hours to complete its work.

700°C, falling to 100°C in the course of the process, in

order to eliminate residual stress and to ensure dimen- The result

sional stability. Finally, the supporting structures are The result is a delicately shaped component with wall

removed and the component is separated from the tray. thicknesses between a minimum of only one millimetre

In the next production stage, the surface is smoothed in and a maximum of four millimetres.

a combined mechanical, physical and chemical process

which drastically improves its fatigue strength, i.e. the “It was a very moving moment for the team when we held

long-term durability of the component in later vehicle our first titanium brake caliper from the 3D printer in our

operation. Finally, the contours of functional surfaces, hands,” Frank Götzke remembers. “In terms of volume,

such as the piston contact surfaces or threads, are this is the largest functional component produced from

titanium by additive manufacturing methods. Everyone

who looks at the part is surprised at how light it is –

despite its large size. Technically, this is an extremely

impressive brake caliper, and it also looks great.”

The first trials for use in production vehicles are due to

be held in the first half of the year; the time schedule

is still to be finalized. At that stage, the engineer

promises that it will be possible to considerably shorten

production times, especially for machining.

The 3D printed titanium brake caliper is only one

example of Bugatti’s current research and development

work. The board only weighs 0.4 kg, half the weight of

a conventional die-cast lightweight aluminium board,

without any reduction in rigidity. But that is another

story.

Prof. Dr.-Ing. Claus Emmelmann, formerly Managing

Director of Laser Zentrum Nord and now, after its

incorporation in the Fraunhofer research organization,

Head of the Fraunhofer Institute for Additive Production

Technologies (Fraunhofer IAPT)

Magazine / February 2018