Page 30 - 3DA Mag N° February2018 -EN+

P. 30

MEDICINE

A 3D PRINTED

anti-pollution mask for children

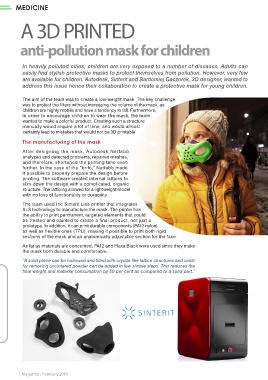

In heavily polluted cities, children are very exposed to a number of diseases. Adults can

easily find stylish protective masks to protect themselves from pollution. However, very few

are available for children. Autodesk, Sinterit and Bartlomiej Gaczorek, 3D designer, wanted to

address this issue hence their collaboration to create a protective mask for young children.

The aim of the team was to create a low-weight mask. The key challenge

was to protect the filters without increasing the volume of the mask, as

children are highly mobile and have a tendency to fall. Furthermore,

in order to encourage children to wear the mask, the team

wanted to make a colorful product. Creating such a structure

manually would require a lot of time, and would almost

certainly lead to mistakes that would not be 3D printable.

The manufacturing of the mask

After designing the mask, Autodesk Netfabb

analyzed and detected problems, repaired meshes,

and therefore, shortened the printing time even

further. In the case of the “brifo,” Netfabb made

it possible to properly prepare the design before

printing. The software created internal lattices to

slim-down the design with a complicated, organic

structure. The latticing allowed for a lightweight model

with no loss of functionality or durability.

The team used the Sinterit Lisa printer that integrates

SLS technology to manufacture the mask. The printer has

the ability to print permanent, targeted elements that could

be treated and painted to create a final product, not just a

prototype. In addition, it can print durable components (PA12 nylon)

as well as flexible ones (TPU), making it possible to print both rigid

sections of the mask and an anatomically adjustable section for the face.

As far as materials are concerned, PA12 and Flexa Black were used since they make

the mask both durable and comfortable.

“A solid piece can be hollowed and filled with crystal-like lattice structures and vents

for removing unsintered powder can be added in few simple steps. This reduces the

final weight and material consumption by 50 per cent as compared to a solid part.”

Magazine / February 2018