Page 21 - Industrial Technology EXTRA 8th February 2021

P. 21

CONTROL PRODUCTS EXTRA ‘FOCUS’

AI software facilitates condition

monitoring of CNC machine tools

UM has launched innovative artificial to ensure that the data is as comprehensive and

intelligence software that provides reliable as possible.

CNC machine tool users with highly The collected data is used to teach a neural

Ncost-effective condition monitoring network so that any deviation from the ‘good’

capabilities. Compatible with all of NUM’s latest- machine behaviour and performance can then be

generation Flexium+ CNC systems, the NUMai detected and predicted; a suitable PC program

software package is a complete, fully integrated for subsequent online performance monitoring

solution for CNC machine tools – it does not and diagnostic purposes is generated

require any additional sensors, and runs on the automatically.

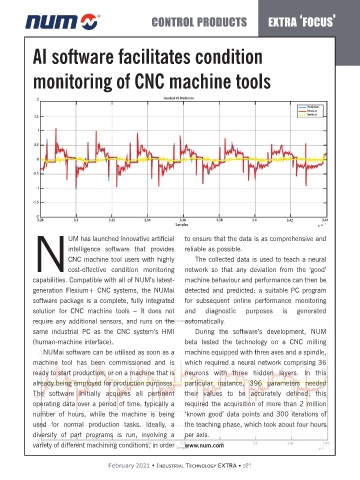

same industrial PC as the CNC system’s HMI During the software’s development, NUM

(human-machine interface). beta tested the technology on a CNC milling

NUMai software can be utilised as soon as a machine equipped with three axes and a spindle,

machine tool has been commissioned and is which required a neural network comprising 36

ready to start production, or on a machine that is neurons with three hidden layers. In this

already being employed for production purposes. particular instance, 396 parameters needed

The software initially acquires all pertinent their values to be accurately defined; this

operating data over a period of time, typically a required the acquisition of more than 2 million

number of hours, while the machine is being ‘known good’ data points and 300 iterations of

used for normal production tasks. Ideally, a the teaching phase, which took about four hours

diversity of part programs is run, involving a per axis.

variety of different machining conditions, in order www.num.com

February 2021 • INDUSTRIAL TECHNOLOGY EXTRA • p21