Page 10 - Industrial_Technology_EXTRA_May_18th_2020_Classical

P. 10

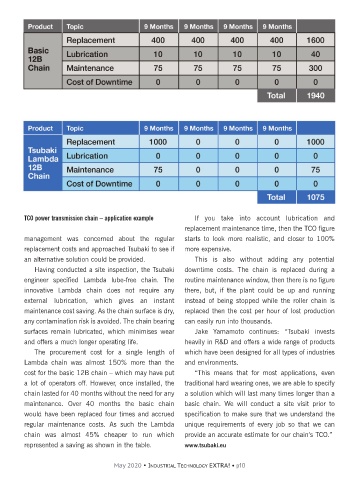

TCO power transmission chain – application example If you take into account lubrication and

replacement maintenance time, then the TCO figure

management was concerned about the regular starts to look more realistic, and closer to 100%

replacement costs and approached Tsubaki to see if more expensive.

an alternative solution could be provided. This is also without adding any potential

Having conducted a site inspection, the Tsubaki downtime costs. The chain is replaced during a

engineer specified Lambda lube-free chain. The routine maintenance window, then there is no figure

innovative Lambda chain does not require any there, but, if the plant could be up and running

external lubrication, which gives an instant instead of being stopped while the roller chain is

maintenance cost saving. As the chain surface is dry, replaced then the cost per hour of lost production

any contamination risk is avoided. The chain bearing can easily run into thousands.

surfaces remain lubricated, which minimises wear Jake Yamamoto continues: “Tsubaki invests

and offers a much longer operating life. heavily in R&D and offers a wide range of products

The procurement cost for a single length of which have been designed for all types of industries

Lambda chain was almost 150% more than the and environments.

cost for the basic 12B chain – which may have put “This means that for most applications, even

a lot of operators off. However, once installed, the traditional hard wearing ones, we are able to specify

chain lasted for 40 months without the need for any a solution which will last many times longer than a

maintenance. Over 40 months the basic chain basic chain. We will conduct a site visit prior to

would have been replaced four times and accrued specification to make sure that we understand the

regular maintenance costs. As such the Lambda unique requirements of every job so that we can

chain was almost 45% cheaper to run which provide an accurate estimate for our chain’s TCO.”

represented a saving as shown in the table. www.tsubaki.eu

May 2020 • INDUSTRIAL TECHNOLOGY EXTRA! • p10