Page 20 - Industrial Technology EXTRA 8th June 2020

P. 20

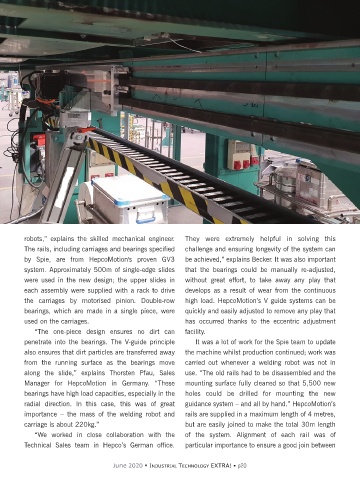

robots,” explains the skilled mechanical engineer. They were extremely helpful in solving this

The rails, including carriages and bearings specified challenge and ensuring longevity of the system can

by Spie, are from HepcoMotion's proven GV3 be achieved,” explains Becker. It was also important

system. Approximately 500m of single-edge slides that the bearings could be manually re-adjusted,

were used in the new design; the upper slides in without great effort, to take away any play that

each assembly were supplied with a rack to drive develops as a result of wear from the continuous

the carriages by motorised pinion. Double-row high load. HepcoMotion’s V guide systems can be

bearings, which are made in a single piece, were quickly and easily adjusted to remove any play that

used on the carriages. has occurred thanks to the eccentric adjustment

“The one-piece design ensures no dirt can facility.

penetrate into the bearings. The V-guide principle It was a lot of work for the Spie team to update

also ensures that dirt particles are transferred away the machine whilst production continued; work was

from the running surface as the bearings move carried out whenever a welding robot was not in

along the slide,” explains Thorsten Pfau, Sales use. “The old rails had to be disassembled and the

Manager for HepcoMotion in Germany. “These mounting surface fully cleaned so that 5,500 new

bearings have high load capacities, especially in the holes could be drilled for mounting the new

radial direction. In this case, this was of great guidance system – and all by hand.” HepcoMotion’s

importance – the mass of the welding robot and rails are supplied in a maximum length of 4 metres,

carriage is about 220kg.” but are easily joined to make the total 30m length

“We worked in close collaboration with the of the system. Alignment of each rail was of

Technical Sales team in Hepco’s German office. particular importance to ensure a good join between

June 2020 • INDUSTRIAL TECHNOLOGY EXTRA! • p20