Page 8 - Industrial Technology E XTRA 24th August 2020

P. 8

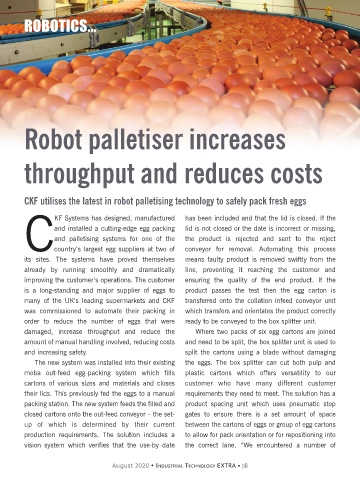

ROBOTICS...

Robot palletiser increases

throughput and reduces costs

CKF utilises the latest in robot palletising technology to safely pack fresh eggs

KF Systems has designed, manufactured has been included and that the lid is closed. If the

and installed a cutting-edge egg packing lid is not closed or the date is incorrect or missing,

and palletising systems for one of the the product is rejected and sent to the reject

Ccountry’s largest egg suppliers at two of conveyor for removal. Automating this process

its sites. The systems have proved themselves means faulty product is removed swiftly from the

already by running smoothly and dramatically line, preventing it reaching the customer and

improving the customer’s operations. The customer ensuring the quality of the end product. If the

is a long-standing and major supplier of eggs to product passes the test then the egg carton is

many of the UK’s leading supermarkets and CKF transferred onto the collation infeed conveyor unit

was commissioned to automate their packing in which transfers and orientates the product correctly

order to reduce the number of eggs that were ready to be conveyed to the box splitter unit.

damaged, increase throughput and reduce the Where two packs of six egg cartons are joined

amount of manual handling involved, reducing costs and need to be split, the box splitter unit is used to

and increasing safety. split the cartons using a blade without damaging

The new system was installed into their existing the eggs. The box splitter can cut both pulp and

moba out-feed egg-packing system which fills plastic cartons which offers versatility to our

cartons of various sizes and materials and closes customer who have many different customer

their lids. This previously fed the eggs to a manual requirements they need to meet. The solution has a

packing station. The new system feeds the filled and product spacing unit which uses pneumatic stop

closed cartons onto the out-feed conveyor – the set- gates to ensure there is a set amount of space

up of which is determined by their current between the cartons of eggs or group of egg cartons

production requirements. The solution includes a to allow for pack orientation or for repositioning into

vision system which verifies that the use-by date the correct lane. “We encountered a number of

August 2020 • INDUSTRIAL TECHNOLOGY EXTRA • p8