Page 132 - Safety Memo

P. 132

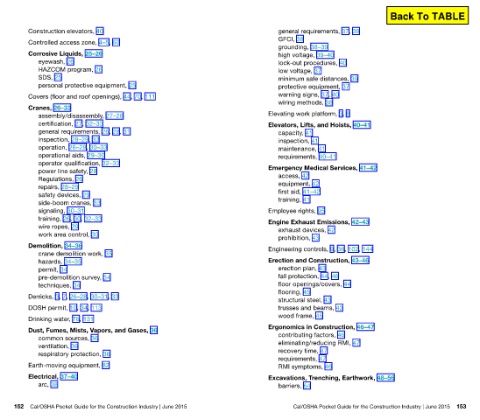

Back To TABLE

Construction elevators, 40 general requirements, 37, 39

GFCI, 38

Controlled access zone, 4–5, 60

grounding, 38–39

Corrosive Liquids, 25–26 high voltage, 39–40

eyewash, 26 lock-out procedures, 40

HAZCOM program, 26 low voltage, 37

SDS, 25 minimum safe distances, 39

personal protective equipment, 25 protective equipment, 37

Covers (floor and roof openings), 44, 70, 111 warning signs, 37, 40

wiring methods, 38

Cranes, 26–33

assembly/disassembly, 27–28 Elevating work platform, 3, 8

certification, 27, 32–33 Elevators, Lifts, and Hoists, 40–41

general requirements, 26, 28, 31 capacity, 41

inspection, 28–29, 33 inspection, 41

operation, 26–28, 30–33 maintenance, 41

operational aids, 29–30 requirements, 40–41

operator qualification, 32–33

power line safety, 28 Emergency Medical Services, 41–42

Regulations, 26 access, 42

repairs, 28–29 equipment, 42

safety devices, 29 first aid, 41–42

side-boom cranes, 33 training, 41

signaling, 30–31 Employee rights, 95

training, 26, 30, 32–33 Engine Exhaust Emissions, 42–43

wire ropes, 29 exhaust devices, 42

work area control, 30

prohibition, 43

Demolition, 34–36 Engineering controls, 9, 36, 102, 144

crane demolition work, 35

hazards, 34–35 Erection and Construction, 43–46

permit, 34 erection plan, 43

pre-demolition survey, 34 fall protection, 44, 46

techniques, 34 floor openings/covers, 44

flooring, 45

Derricks, 3, 7, 26–28, 30–31, 33

structural steel, 43

DOSH permit, 10, 34, 113 trusses and beams, 43

Drinking water, 76, 131 wood frame, 45

Ergonomics in Construction, 46–47

Dust, Fumes, Mists, Vapors, and Gases, 36

common sources, 36 contributing factors, 46

ventilation, 36 eliminating/reducing RMI, 47

respiratory protection, 36 recovery time, 47

requirements, 47

Earth-moving equipment, 82 RMI symptoms, 46

Electrical, 37–40 Excavations, Trenching, Earthwork, 48–56

arc, 38 barriers, 64

152 Cal/OSHA Pocket Guide for the Construction Industry | June 2015 Cal/OSHA Pocket Guide for the Construction Industry | June 2015 153