Page 13 - Waterlife Magazine Issue 1 2018

P. 13

Continuous Supplies Vehicle New Camera Locates Leaks

Launch of continuous supplies vehicle proving Camera saves unnecessary

to be highly successful excavations after locating leaks immediately

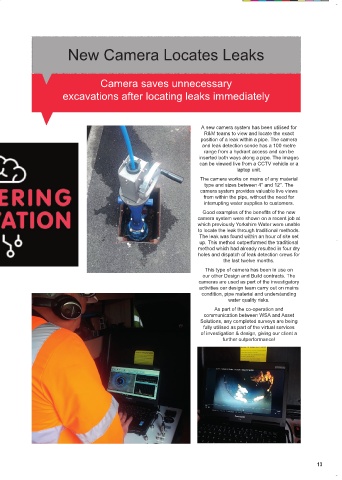

A continuous supply vehicle has been put into A new camera system has been utilised for

action on the WSA contract to help reduce R&M teams to view and locate the exact

the risk of interruptions to supply. The vehicle position of a leak within a pipe. The camera

contains equipment that allows the onsite team and leak detection sonde has a 100 metre

to repair multiple issues immediately, without range from a hydrant access and can be

disrupting the water supply to the customer. inserted both ways along a pipe. The images

can be viewed live from a CCTV vehicle or a

This is not the fi rst time MUS have used these

vehicles, the initial trials were carried out in laptop unit.

2015 on the Asset Solutions contract. Rigorous The camera works on mains of any material

testing of the equipment and the process of type and sizes between 4’’ and 12’’. The

setting up on site, connecting to the network, camera system provides valuable live views

health and safety of the general public and from within the pipe, without the need for

demobilising were completed satisfactorily prior interrupting water supplies to customers.

to deployment across lead service replacement

projects. The sharing of this information Good examples of the benefi ts of the new

was vital in the continuous collaboration camera system were shown on a recent job at

between the two contracts, providing The current CSVs are operated out of two which previously Yorkshire Water were unable

opportunities to outperform for our client. to locate the leak through traditional methods.

MUS depots; Ecclesfi eld (Sheffi eld) and The leak was found within an hour of site set

The most recent successful deployment was Chellow (Bradford). The plan is to extend the up. This method outperformed the traditional

on Lady Bark Lane, Wakefi eld. The team were use of CSVs to three further depots to give full method which had already resulted in four dry

informed of a vulnerable customer (dialysis coverage of the whole of the Yorkshire region. holes and dispatch of leak detection crews for

patient). The deployment of the CSV meant that Customers benefi t from reduced risk of supply the last twelve months.

the customer was unaffected by any interruption interruptions and Yorkshire Water benefi t

to supply whilst the repair was completed. in terms of regulatory service performance. This type of camera has been in use on

our other Design and Build contracts. The

cameras are used as part of the investigatory

activities our design team carry out on mains

condition, pipe material and understanding

water quality risks.

Live Valve Insertion Proves to be a Success As part of the co-operation and

communication between WSA and Asset

Solutions, any completed surveys are being

A live valve insertion concept has been fully utilised as part of the virtual services

designed to ensure no interruption to of investigation & design, giving our client a

customer’s water supply whilst inserting further outperformance!

an ‘in-line’ valve. The 8in valve was

inserted and proved to be successful

without any issues to the network or

operations.

From start to fi nish the insertion was

completed in just 1 ½ hours. This saved

a whopping 300 customers from risk of

supply interruption (Yorkshire Water’s

Customer Minutes Lost target).

This method has shown great

outperformance. It is a faster, more

convenient way to install valves. It is also

more environmentally friendly because

only one excavation is required.

12 13

Waterlife 20092018 v8.indd 12-13 06/12/2018 09:04:51