Page 24 - O Bunge Oils Resource Guide

P. 24

FRiED FOOD qUALiTY CONTROL

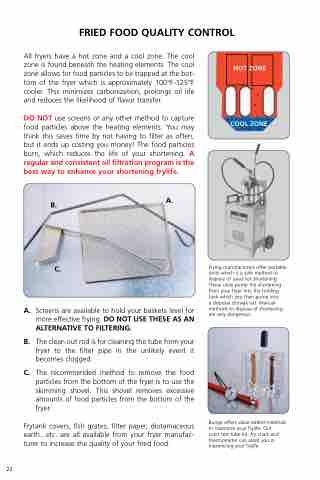

All fryers have a hot zone and a cool zone . The cool zone is found beneath the heating elements . The cool zone allows for food particles to be trapped at the bot- tom of the fryer which is approximately 100°F-125°F cooler . This minimizes carbonization, prolongs oil life and reduces the likelihood of flavor transfer .

DO NOT use screens or any other method to capture food particles above the heating elements . You may think this saves time by not having to filter as often, but it ends up costing you money! The food particles burn, which reduces the life of your shortening . A regular and consistent oil filtration program is the best way to enhance your shortening frylife.

COOL zONE

hOT

zONE

B.

C.

A.

Frying manufacturers offer portable units which is a safe method to dispose of used hot shortening . These units pump the shortening from your fryer into the holding tank which you then pump into

a disposal storage vat . Manual methods to dispose of shortening are very dangerous .

A. Screens are available to hold your baskets level for more effective frying . DO NOT USE ThESE AS AN ALTERNATiVE TO FiLTERiNG.

B. The clean out rod is for cleaning the tube from your fryer to the filter pipe in the unlikely event it becomes clogged .

C. The recommended method to remove the food particles from the bottom of the fryer is to use the skimming shovel . This shovel removes excessive amounts of food particles from the bottom of the fryer .

Frytank covers, fish grates, filter paper, diotamaceous earth . . .etc . are all available from your fryer manufac- turer to increase the quality of your fried food .

23

Bunge offers value added materials to maximize your frylife . Our

color test tube kit, fry chart and thermometer can assist you in maximizing your frylife .