Page 50 - Green Builder Magazine Nov-Dec 2017 Issue

P. 50

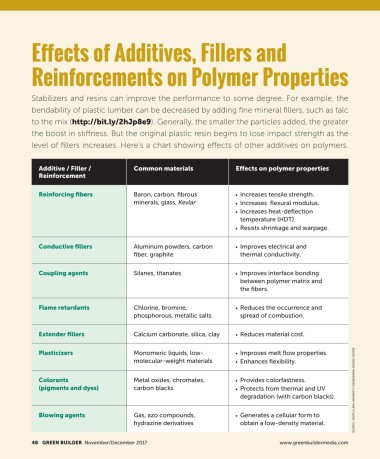

Effects of Additives, Fillers and

Reinforcements on Polymer Properties

Stabilizers and resins can improve the performance to some degree. For example, the

bendability of plastic lumber can be decreased by adding fine mineral fillers, such as talc

to the mix (http://bit.ly/2hJp8e9). Generally, the smaller the particles added, the greater

the boost in stiffness. But the original plastic resin begins to lose impact strength as the

level of fillers increases. Here’s a chart showing effects of other additives on polymers.

Additive / Filler / Common materials Effects on polymer properties

Reinforcement

Reinforcing fibers Baron, carbon, fibrous ■ ■ Increases tensile strength.

minerals, glass, Kevlar ■ ■ Increases flexural modulus.

■ Increases heat-deflection

■

temperature (HDT).

■ Resists shrinkage and warpage.

■

Conductive fillers Aluminum powders, carbon ■ ■ Improves electrical and

fiber, graphite thermal conductivity.

Coupling agents Silanes, titanates ■ ■ Improves interface bonding

between polymer matrix and

the fibers.

Flame retardants Chlorine, bromine, ■ ■ Reduces the occurrence and

phosphorous, metallic salts spread of combustion.

Extender fillers Calcium carbonate, silica, clay ■ ■ Reduces material cost.

SOURCE: SANTA CLARA UNIVERSITY ENGINEERING DESIGN CENTER

Plasticizers Monomeric liquids, low- ■ ■ Improves melt flow properties.

molecular-weight materials ■ ■ Enhances flexibility.

Colorants Metal oxides, chromates, ■ ■ Provides colorfastness.

(pigments and dyes) carbon blacks ■ Protects from thermal and UV

■

degradation (with carbon blacks).

Blowing agents Gas, azo compounds, ■ ■ Generates a cellular form to

hydrazine derivatives obtain a low-density material.

48 GREEN BUILDER November/December 2017 www.greenbuildermedia.com

44-51 GB 1117 Perils of Plastic.indd 48 11/17/17 11:32 AM