Page 118 - ro membanes

P. 118

5.2 BAR, BAND, AND DRUM SCREENS 101

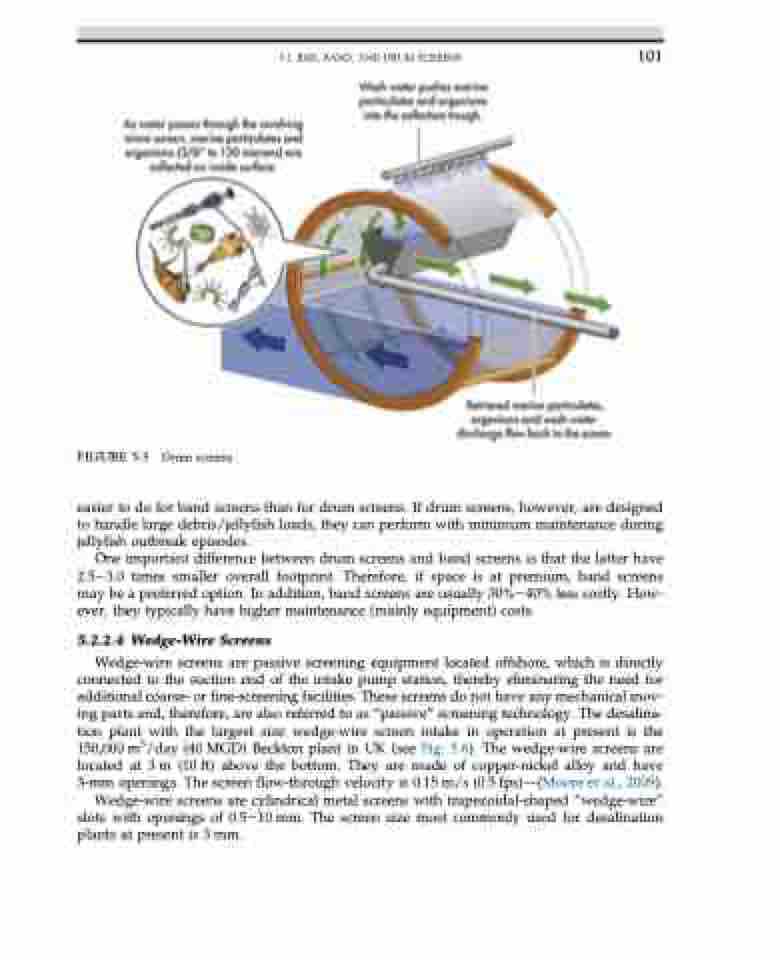

FIGURE 5.5 Drum screens.

easier to do for band screens than for drum screens. If drum screens, however, are designed to handle large debris/jellyfish loads, they can perform with minimum maintenance during jellyfish outbreak episodes.

One important difference between drum screens and band screens is that the latter have 2.5e3.0 times smaller overall footprint. Therefore, if space is at premium, band screens may be a preferred option. In addition, band screens are usually 30%e40% less costly. How- ever, they typically have higher maintenance (mainly equipment) costs.

5.2.2.4 Wedge-Wire Screens

Wedge-wire screens are passive screening equipment located offshore, which is directly connected to the suction end of the intake pump station, thereby eliminating the need for additional coarse- or fine-screening facilities. These screens do not have any mechanical mov- ing parts and, therefore, are also referred to as “passive” screening technology. The desalina- tion plant with the largest size wedge-wire screen intake in operation at present is the 150,000 m3/day (40 MGD) Beckton plant in UK (see Fig. 5.6). The wedge-wire screens are located at 3 m (10 ft) above the bottom. They are made of copper-nickel alloy and have 3-mm openings. The screen flow-through velocity is 0.15 m/s (0.5 fps)d(Moore et al., 2009).

Wedge-wire screens are cylindrical metal screens with trapezoidal-shaped “wedge-wire” slots with openings of 0.5e10 mm. The screen size most commonly used for desalination plants at present is 3 mm.