Page 233 - ro membanes

P. 233

216 9. MEMBRANE FILTRATION

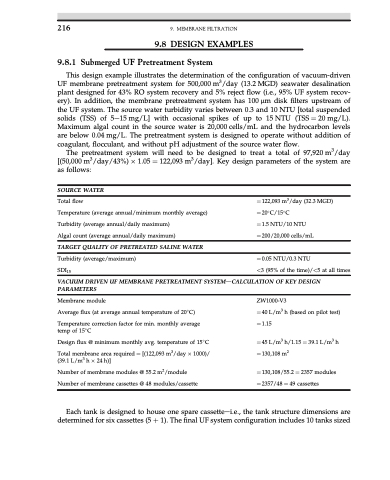

9.8 DESIGN EXAMPLES

9.8.1 Submerged UF Pretreatment System

This design example illustrates the determination of the configuration of vacuum-driven UF membrane pretreatment system for 500,000 m3/day (13.2 MGD) seawater desalination plant designed for 43% RO system recovery and 5% reject flow (i.e., 95% UF system recov- ery). In addition, the membrane pretreatment system has 100 mm disk filters upstream of the UF system. The source water turbidity varies between 0.3 and 10 NTU [total suspended solids (TSS) of 5e15mg/L] with occasional spikes of up to 15NTU (TSS1⁄420mg/L). Maximum algal count in the source water is 20,000 cells/mL and the hydrocarbon levels are below 0.04 mg/L. The pretreatment system is designed to operate without addition of coagulant, flocculant, and without pH adjustment of the source water flow.

The pretreatment system will need to be designed to treat a total of 97,920 m3/day [(50,000 m3/day/43%) 1.05 1⁄4 122,093 m3/day]. Key design parameters of the system are as follows:

SOURCE WATER

Total flow

Temperature (average annual/minimum monthly average)

Turbidity (average annual/daily maximum)

Algal count (average annual/daily maximum)

TARGET QUALITY OF PRETREATED SALINE WATER

Turbidity (average/maximum)

SDI15

1⁄4 122,093 m3/day (32.3 MGD) 1⁄4 20 C/15 C

1⁄4 1.5 NTU/10 NTU

1⁄4 200/20,000 cells/mL

1⁄4 0.05 NTU/0.3 NTU

<3 (95% of the time)/<5 at all times

VACUUM DRIVEN UF MEMBRANE PRETREATMENT SYSTEMdCALCULATION OF KEY DESIGN

PARAMETERS

Membrane module

Average flux (at average annual temperature of 20C)

Temperature correction factor for min. monthly average temp of 15C

Design flux @ minimum monthly avg. temperature of 15C Total membrane area required 1⁄4 [(122,093 m3/day 1000)/

(39.1 L/m3 h 24 h)]

Number of membrane modules @ 55.2 m2/module Number of membrane cassettes @ 48 modules/cassette

ZW1000-V3

1⁄4 40 L/m3 h (based on pilot test) 1⁄4 1.15

1⁄4 45 L/m3 h/1.15 1⁄4 39.1 L/m3 h 1⁄4 130,108 m2

1⁄4 130,108/55.2 1⁄4 2357 modules 1⁄4 2357/48 1⁄4 49 cassettes

Each tank is designed to house one spare cassetteei.e., the tank structure dimensions are determined for six cassettes (5 þ 1). The final UF system configuration includes 10 tanks sized