Page 234 - ro membanes

P. 234

9.8 DESIGN EXAMPLES 217

to house six cassettes per tank with five cassettes installed per tank along with connections to sixth cassette. With one tank in backwash and one tank out of service for cleaning, the plant operating flux will be 122,093 m3/day 1000 L/(10 Tanks 5 Cassettes 48 mod- ules 55.2 m2/module 24 h) 1⁄4 38.4 lmh (22.5 gfd). This flux is within the acceptable range of 30e45 L/m2 h (18e26 gfd), determined by pilot testing.

9.8.2 Pressure-Driven UF Pretreatment System

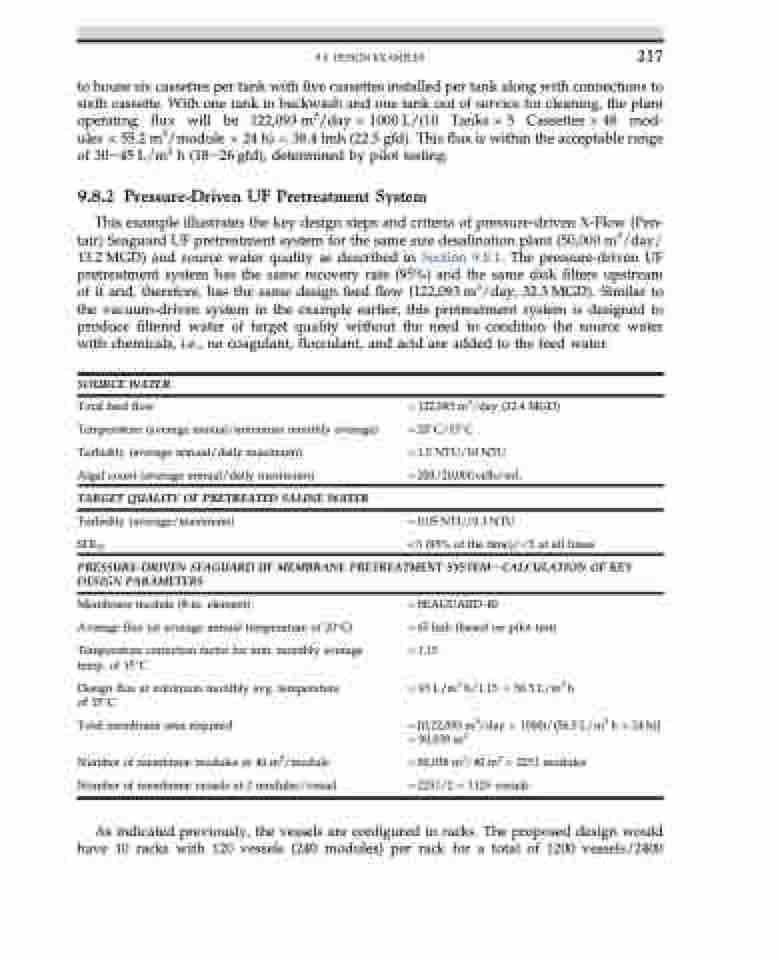

This example illustrates the key design steps and criteria of pressure-driven X-Flow (Pen- tair) Seaguard UF pretreatment system for the same size desalination plant (50,000 m3/day/ 13.2 MGD) and source water quality as described in Section 9.8.1. The pressure-driven UF pretreatment system has the same recovery rate (95%) and the same disk filters upstream of it and, therefore, has the same design feed flow (122,093 m3/day, 32.3 MGD). Similar to the vacuum-driven system in the example earlier, this pretreatment system is designed to produce filtered water of target quality without the need to condition the source water with chemicals, i.e., no coagulant, flocculant, and acid are added to the feed water.

SOURCE WATER

Total feed flow

Temperature (average annual/minimum monthly average)

Turbidity (average annual/daily maximum)

Algal count (average annual/daily maximum)

TARGET QUALITY OF PRETREATED SALINE WATER

Turbidity (average/maximum)

SDI15

1⁄4 122,093 m3/day (32.4 MGD) 1⁄4 20 C/15 C

1⁄4 1.5 NTU/10 NTU

1⁄4 200/20,000 cells/mL

1⁄4 0.05 NTU/0.3 NTU

<3 (95% of the time)/<5 at all times

PRESSURE-DRIVEN SEAGUARD UF MEMBRANE PRETREATMENT SYSTEMdCALCULATION OF KEY

DESIGN PARAMETERS

Membrane module (8-in. element)

Average flux (at average annual temperature of 20C)

Temperature correction factor for min. monthly average temp. of 15C

Design flux at minimum monthly avg. temperature of 15C

Total membrane area required

Number of membrane modules at 40 m2/module Number of membrane vessels at 2 modules/vessel

1⁄4 SEAGUARD 40

1⁄4 65 lmh (based on pilot test) 1⁄4 1.15

1⁄4 65 L/m3 h/1.15 1⁄4 56.5 L/m3 h

1⁄4[(122,093 m3/day 1000)/(56.5 L/m3 h 24 h)]

1⁄4 90,039 m2

1⁄4 90,039 m2/40 m2 1⁄4 2251 modules 1⁄4 2251/2 1⁄4 1125 vessels

As indicated previously, the vessels are configured in racks. The proposed design would have 10 racks with 120 vessels (240 modules) per rack for a total of 1200 vessels/2400