Page 51 - Georgia Commercial Drivers Manual 2020

P. 51

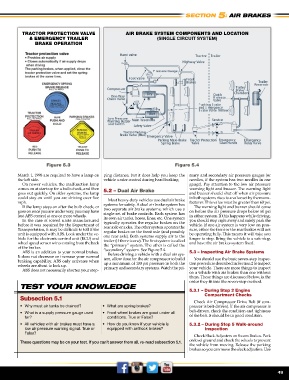

TRACTOR PROTECTION VALVE 5SECTION : AIR BRAKES

& EMERGENCY TRAILER

BRAKE OPERATION AIR BRAKE SYSTEM COMPONENTS AND LOCATION

(SINGLE CIRCUIT SYSTEM)

Figure 5.3 Figure 5.4

March 1, 1998 are required to have a lamp on ping distance, but it does help you keep the mary and secondary air pressure gauges (or

the left side. vehicle under control during hard braking. needles, if the system has two needles in one

gauge). Pay attention to the low air pressure

On newer vehicles, the malfunction lamp 5.2 – Dual Air Brake warning light and buzzer. The warning light

comes on at start-up for a bulb check, and then and buzzer should shut off when air pressure

goes out quickly. On older systems, the lamp Most heavy-duty vehicles use dual air brake in both systems rises to a value set by the manu-

could stay on until you are driving over five systems for safety. A dual air brake system has facturer. This value must be greater than 60 psi.

mph. two separate air brake systems, which use a

single set of brake controls. Each system has The warning light and buzzer should come

If the lamp stays on after the bulb check, or its own air tanks, hoses, lines, etc. One system on before the air pressure drops below 60 psi

goes on once you are under way, you may have typically operates the regular brakes on the in either system. If this happens while driving,

lost ABS control at one or more wheels. rear axle or axles. The other system operates the you should stop right away and safely park the

regular brakes on the front axle (and possibly vehicle. If one air system is very low on pres-

In the case of towed units manufactured one rear axle). Both systems supply air to the sure, either the front or the rear brakes will not

before it was required by the Department of trailer (if there is one). The first system is called be operating fully. This means it will take you

Transportation, it may be difficult to tell if the the “primary” system. The other is called the longer to stop. Bring the vehicle to a safe stop,

unit is equipped with ABS. Look under the ve- “secondary” system. See Figure 5.4. and have the air brakes system fixed.

hicle for the electronic control unit (ECU) and

wheel speed sensor wires coming from the back Before driving a vehicle with a dual air sys- 5.3 – Inspecting Air Brake Systems

of the brakes. tem, allow time for the air compressor to build You should use the basic seven-step inspec-

up a minimum of 100 psi pressure in both the

ABS is an addition to your normal brakes. primary and secondary systems. Watch the pri- tion procedure described in Section 2 to inspect

It does not decrease or increase your normal your vehicle. There are more things to inspect

braking capability. ABS only activates when on a vehicle with air brakes than one without

wheels are about to lock up. them. These things are discussed below, in the

order they fit into the seven-step method.

ABS does not necessarily shorten your stop-

5.3.1 – During Step 2 Engine

TEST YOUR KNOWLEDGE Compartment Checks

Subsection 5.1 • What are spring brakes? Check Air Compressor Drive Belt (if com-

• Front wheel brakes are good under all pressor is belt-driven). If the air compressor is

• Why must air tanks be drained? belt-driven, check the condition and tightness

• What is a supply pressure gauge used conditions. True or False? of the belt. It should be in good condition.

• How do you know if your vehicle is

for? 5.3.2 – During Step 5 Walk-around

• All vehicles with air brakes must have a equipped with antilock brakes? Inspection

low air pressure warning signal. True or Check Slack Adjusters on S-cam Brakes. Park

False? on level ground and chock the wheels to prevent

the vehicle from moving. Release the parking

These questions may be on your test. If you can’t answer them all, re-read subsection 5.1. brakes so you can move the slack adjusters. Use

49