Page 61 - Georgia Commercial Drivers Manual 2020

P. 61

6SECTION : COMBINATION VEHICLES

• Tighten in both the lock screws (2, 2a) to- • Loosen safety lock screw (2a) and remove Step 3. Install Safety Pin and Clip

gether with their relative self-locking nuts (12, safety lock screw (2) together with its self-

12a) at a 350 to 400 Nm torque wrench setting. locking nut (12). • Install safety pin and clip. (Fig. B)

Step 5. Adjust the Adjustment Screw Step 3. Rotate Safety Cover Bar and Lift

• Adjust the adjustment screw (3) until a 0.3 - Trailer Drawbeam

0.5 mm vertical clearance between the guard • Rotate the safety cover bar (4) outwards so

disk (13) and the ball cup (6) is reached. Lock that it is completely open.

setting with counter nut (11).

• Lift the trailer drawbeam until the drawbar

coupling ball (5) is fully visible, then travel

forward with the trailer very slowly.

• Rotate the safety cover bar inwards (4) until

it lodges back in its housing.

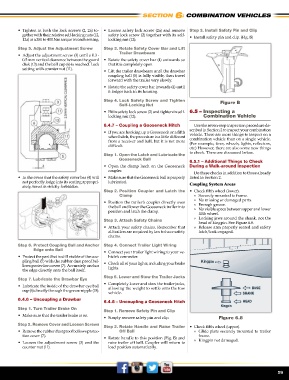

Step 4. Lock Safety Screw and Tighten Figure B

Self-Locking Nut 6.5 – Inspecting a

• Fit in safety lock screw (2) and tighten in self- Combination Vehicle

locking nut (12).

• In the event that the safety cover bar (4) will 6.4.7 – Coupling a Gooseneck Hitch Use the seven-step inspection procedure de-

not perfectly lodge into its seating appropri- • If you are hooking up a Gooseneck or a fifth scribed in Section 2 to inspect your combination

ately, travel is strictly forbidden. vehicle. There are more things to inspect on a

wheel hitch, the procedure is a little different combination vehicle than on a single vehicle.

from a receiver and ball, but it is not more (For example, tires, wheels, lights, reflectors,

difficult. etc.) However, there are also some new things

to check. These are discussed below.

Step 1. O pen the Latch and Lubricate the

Gooseneck Ball 6.5.1 – Additional Things to Check

During a Walk-around Inspection

• Open the clamp latch on the Gooseneck

coupler. Do these checks in addition to those already

listed in Section 2.

• Make sure that the Gooseneck ball is properly Coupling System Areas

lubricated. • Check fifth wheel (lower).

Step 2. P osition Coupler and Latch the »» Securely mounted to frame.

Clamp »» No missing or damaged parts.

»» Enough grease.

• Position the trailer’s coupler directly over »» No visible space between upper and lower

the ball and lower the Gooseneck trailer into

position and latch the clamp. fifth wheel.

»» Locking jaws around the shank, not the

Step 3. Attach Safety Chains

• Attach your safety chains. Remember that head of kingpin. See Figure 6.8.

»» Release arm properly seated and safety

all trailers are required by law to have safety

chains. latch/lock engaged.

Step 6. P rotect Coupling Ball and Anchor Step 4. Connect Trailer Light Wiring Figure 6.8

Edge onto Ball • Connect your trailer light wiring to your ve- • Check fifth wheel (upper).

• Protect the part that is still visible of the cou- hicle’s connector. »» Glide plate securely mounted to trailer

pling ball (5) with the rubber dust proof bel- • Check all of your lights, including your brake frame.

lows protection cover (7). Accurately anchor

the edge directly onto the ball itself. lights. »» Kingpin not damaged.

Step 7. Lubricate the Drawbar Eye Step 5. Lower and Stow the Trailer Jacks

• Lubricate the inside of the drawbar eye ball • Completely lower and stow the trailer jacks,

cup (6) directly through the grease nipple (18). allowing the weight to settle onto the tow

vehicle.

6.4.6 – Uncoupling a Drawbar

6.4.8 – Uncoupling a Gooseneck Hitch

Step 1. Turn Trailer Brake On

• Make sure that the trailer brake is on. Step 1. Remove Safety Pin and Clip

• Simply remove safety pin and clip.

Step 2. Remove Cover and Loosen Screws

• Remove the rubber dust proof bellows protec- Step 2. R otate Handle and Raise Trailer

Off Ball

tion cover (7).

• Loosen the adjustment screw (3) and the • Rotate handle to this position (Fig. B) and

raise trailer off ball. Coupler will return to

counter nut (11). load position automatically.

59