Page 25 - KCRPCA MayJune 2021

P. 25

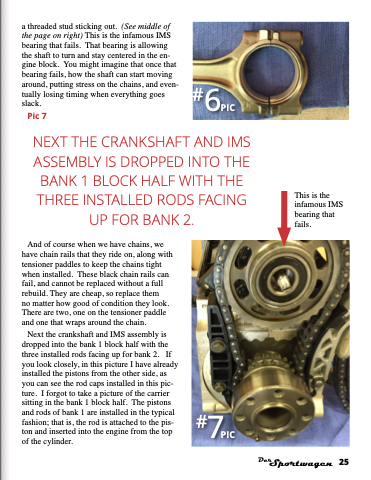

a threaded stud sticking out. (See middle of the page on right) This is the infamous IMS bearing that fails. That bearing is allowing the shaft to turn and stay centered in the en- gine block. You might imagine that once that bearing fails, how the shaft can start moving around, putting stress on the chains, and even- tually losing timing when everything goes slack.

Pic 7

6

#

PIC

NEXT THE CRANKSHAFT AND IMS ASSEMBLY IS DROPPED INTO THE BANK 1 BLOCK HALF WITH THE THREE INSTALLED RODS FACING UP FOR BANK 2.

And of course when we have chains, we have chain rails that they ride on, along with tensioner paddles to keep the chains tight when installed. These black chain rails can fail, and cannot be replaced without a full rebuild. They are cheap, so replace them

no matter how good of condition they look. There are two, one on the tensioner paddle and one that wraps around the chain.

This is the infamous IMS bearing that fails.

Next the crankshaft and IMS assembly is

dropped into the bank 1 block half with the

three installed rods facing up for bank 2. If

you look closely, in this picture I have already

installed the pistons from the other side, as

you can see the rod caps installed in this pic-

ture. I forgot to take a picture of the carrier

sitting in the bank 1 block half. The pistons 7 and rods of bank 1 are installed in the typical # fashion; that is, the rod is attached to the pis-

PIC

ton and inserted into the engine from the top of the cylinder.

Der Sportwagen

25