Page 16 - Wilger Catalog

P. 16

NN OO

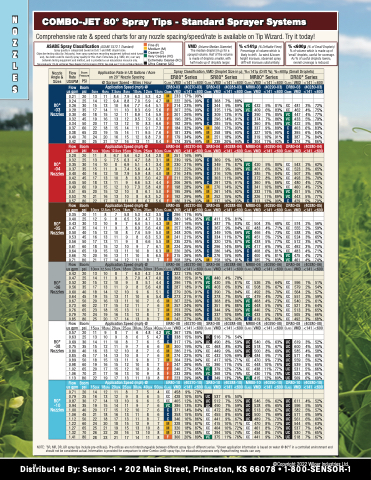

COMBO-JET 80° Spray Tips - Standard Sprayer Systems Comprehensive rate & speed charts for any nozzle spacing/speed/rate is available on Tip Wizard. Try it today!

Z Z Z

ASABE Spray Classification (ASABE S572.1 Standard)

Spray quality is categorized based on Dv0.1 and VMD droplet sizes.

Objective testing data (by 3rd party), from spray spectrum recording equipment (without wind tunnel use), has been used to classify spray quality for this chart. Extra data (e.g. VMD, etc.) can vary between testing equipment and method, and is provided as an educational resource only.

Tips sized up to 110-06 verified on Phase Doppler Particle Analyzer (PDPA); tips sized over 110-06 verified on Malvern.

Fine (F)

Medium (M)

Coarse (C)

Very Coarse (VC) Extremely Coarse (XC) Ultra Coarse (UC)

VMD (Volume Median Diameter) The median droplet (in μ) for a sprayed volume. Half of the volume is made of droplets smaller, with half made up of droplets larger.

% <141μ (% Driftable Fines) Percentage of volume which is likely to drift. As wind & boom height increase, observed spray drift will increase substantially.

% <600μ (% of Small Droplets) % of volume which is made up of ‘small’ droplets, useful for coverage. As % of useful droplets lowers, overall coverage is reduced.

L E L

Z

SE S

Nozzle Flow Angle & Rate

Sizes USGPM

Flow us gpm

Boom Pressure

PSI

Application Rate in US Gallons / Acre on 20” Nozzle Spacing

@ Sprayer Speed - Miles / Hour

Spray Classification, VMD (Droplet Size in μ); %<141μ (Drift %); %<600μ (Small Droplets) ER80° Series SR80° Series MR80° Series DR80° Series Class VMD <141 <600 Class VMD <141 <600 Class VMD <141 <600 Class VMD <141 <600

16

NOTE: 1SR, MR, DR, UR spray tips include pre-orifice(s). Pre-orifices are not interchangeable between different spray tips of different series. 2Shown application information is based on water @ 80°F in a controlled environment and should not be considered actual. Information is provided for comparison to other Combo-Jet® spray tips, for educational purposes only. Repeat testing results can vary.

©Copyright 2022 Wilger Industries Ltd.

Nozzles

322 12% 92%

308 15% 91% VC 440 4% 78% 296 17% 91% VC 420 5% 81% 287 18% 91% VC 403 6% 83% 279 20% 91% C 390 7% 84% 273 21% 91% C 378 7% 85%

XC 526 XC 508 XC 492 XC 479 VC 468 VC 448 VC 440 VC 433 C 419 MR80-08

Nozzles

M 300 19% 92% XC 468 8% 63% M 286 21% 93% XC 449 9% 66% M 274 22% 93% XC 432 10% 69% M 264 23% 94% XC 417 10% 71% F 247 26% 95% XC 390 11% 74% F 240 27% 95% VC 379 12% 75% F 233 28% 95% VC 368 12% 76% F 223 29% 96% C 349 13% 78% ER80-10 (40270-10) SR80-10 (40288-10)

0.71 20 14 12 11 8 7 5 4 XC 458 9% 78%

80° 0.87 -10 0.94

30 17 14 35 19 15

UC 546 UC 528 UC 513 UC 500 UC 489 XC 470 XC 461 XC 454 XC 441

Nozzles

1.00

1.06 45 1.12 50 1.22 60 1.27 65 1.32 70 1.41 80

20 17 21 18 22 18 24 20 25 21 26 22 28 23

Application Speed (mph) @

psi 5Gpa 6Gpa 7.5Gpa 8Gpa 10Gpa 12Gpa 15Gpa Class VMD <141 <600 Class VMD <141 <600 Class VMD

(40290-03) DR80-03 (40280-03) <141 <600 Class VMD <141 <600

5% 81% XC 481 3% 72% 6% 83% XC 462 4% 75% 7% 85% VC 447 4% 77% 7% 86% VC 433 5% 79% 8% 88% VC 422 5% 80% 9% 89% C 403 6% 83% 10% 90% C 395 6% 84% 10% 91% C 387 7% 84%

11% 92% C 374 7% 86% (40290-04) DR80-04 (40280-04) <141 <600 Class VMD <141 <600

5% 80% XC 543 2% 62% 6% 82% XC 523 3% 65% 7% 84% XC 507 3% 68% 8% 85% XC 493 3% 70% 9% 86% XC 480 4% 72% 10% 88% XC 460 4% 75% 11% 88% VC 451 5% 76% 11% 89% VC 443 5% 77% 12% 90% C 429 5% 79% (40290-05) DR80-05 (40280-05) <141 <600 Class VMD <141 <600

3% 68% XC 574 2% 56% 4% 71% XC 555 2% 59% 4% 73% XC 538 2% 62% 5% 75% XC 524 3% 65% 5% 77% XC 512 3% 67% 6% 79% XC 492 3% 70% 6% 81% XC 483 4% 71% 6% 81% VC 475 4% 72% 7% 83% VC 461 4% 74%

(40290-06) DR80-06 (40280-06) <141 <600 Class VMD <141 <600

2% 64% XC 596 1% 51% 3% 67% XC 579 2% 54% 3% 70% XC 564 2% 57% 4% 72% XC 551 2% 59% 4% 73% XC 540 2% 61% 5% 76% XC 521 3% 64% 5% 77% XC 513 3% 65% 5% 78% XC 505 3% 66% 6% 80% XC 492 3% 68%

(40290-08) DR80-08 (40280-08) <141 <600 Class VMD <141 <600

6% 63% UC 619 3% 52% 7% 67% UC 600 4% 55% 8% 69% UC 585 4% 58% 9% 71% UC 571 4% 60% 9% 73% UC 559 5% 62% 10% 76% UC 539 5% 65% 11% 77% UC 531 5% 66% 11% 78% UC 523 6% 67%

12% 80% UC 509 6% 69% (40290-10) DR80-10 (40280-10) <141 <600 Class VMD <141 <600

5% 62% UC 611 4% 52% 6% 65% UC 596 5% 55% 6% 67% UC 582 5% 57% 7% 69% UC 571 6% 59% 7% 70% UC 561 6% 60% 8% 72% UC 544 6% 63% 8% 73% UC 537 7% 64% 8% 74% UC 530 7% 65% 9% 76% UC 518 7% 67%

Boom

ER80-03 (40270-03) SR80-03 (40288-03) MR80-03

0.21 20 13 11 8.4 7.9 6.3 5.3 4.2 M 23317%99%

0.24 25 14 12 9.4 8.8 7.0 5.9 4.7 M 222 20% 99% C 368 7% 88% 80° 0.26 30 15 13 10 9.6 7.7 6.4 5.1 F 214 23% 99% C 344 9% 89% -03 0.28 35 17 14 11 10 8.3 6.9 5.6 F 207 25% 99% C 325 11% 90%

VC 432 VC 409 C 390 C 374 C 360 C 337 C 327 C 319 C 304 MR80-04

Nozzles

0.30 40 18 15 12 11 8.9 7.4 5.9 F 201 26% 99% C 309 12% 91% 0.32 45 19 16 13 12 9.5 7.9 6.3 F 196 28% 99% C 296 14% 91% 0.34 50 20 17 13 12 10 8.3 6.6 F 192 29% 99% C 285 15% 92% 0.37 60 22 18 15 14 11 9.1 7.3 F 184 32% 99% M 266 17% 93% 0.38 65 23 19 15 14 11 9.5 7.6 F 181 33% 99% M 258 18% 93% 0.40 70 24 20 16 15 12 9.8 7.9 F 179 34% 99% M 251 18% 93% 0.42 80 25 21 17 16 13 11 8.4 F 174 35% 99% M 239 20% 94% Flow Boom Application Speed (mph) @ ER80-04 (40270-04) SR80-04 (40288-04)

us gpm psi 8Gpa 10Gpa 12.5Gpa 15Gpa 20Gpa 25Gpa 30Gpa Class VMD <141 <600 Class VMD <141 <600 Class VMD

0.28 20 11 8 6.7 5.6 4.2 3.4 2.8

M 251 16% 99%

M 239 19% 99% C 369 5% 85% M 230 21% 99% C 349 7% 87% M 222 22% 99% C 331 9% 88% M 216 24% 99% C 316 10% 89%

us gpm psi 10Gpa 12.5Gpa 15Gpa 18Gpa 20Gpa 25Gpa 30Gpa Class VMD <141 <600 Class VMD <141 <600 Class VMD

0.32 25 13 9 7.5 6.3 4.7 3.8 3.1 80° 0.35 30 14 10 8 6.9 5.1 4.1 3.4 -04 0.37 35 15 11 9 7.4 5.6 4.4 3.7

Nozzles

VC 420 VC 401 C 385 C 372 C 360 C 341 C 333 C 326 C 313 MR80-05

0.40 40 16 12 10 7.9 5.9 4.8 4.0

0.42 45 17 13 10 8 6.3 5.0 4.2 F 211 25% 99% C 303 11% 90% 0.45 50 18 13 11 9 6.6 5.3 4.4 F 206 26% 99% C 291 12% 91% 0.49 60 19 15 12 10 7.3 5.8 4.8 F 198 28% 99% M 270 14% 92% 0.51 65 20 15 12 10 8 6.1 5.0 F 195 29% 99% M 261 14% 92% 0.53 70 21 16 13 10 8 6.3 5.2 F 192 29% 99% M 252 15% 92% 0.57 80 22 17 13 11 8 6.7 5.6 F 186 31% 99% M 237 16% 93% Flow Boom Application Speed (mph) @ ER80-05 (40270-05) SR80-05 (40288-05)

0.35 20 11875.8 5.3 4.2

3.5 C 296 11% 95%

3.9 C 280 14% 95% VC 411 5% 81% 4.3 M 267 16% 95% C 387 7% 83% 4.6 M 257 18% 95% C 367 9% 84% 5.0 M 248 20% 95% C 349 10% 86% 5.3 M 241 21% 95% C 334 11% 87% 5.5 M 235 22% 95% C 320 12% 87%

0.40 25 12 9 8 6.5 5.9 4.7 80° 0.43 30 13 10 9 7 6.4 5.1 -05 0.47 35 14 11 9 8 6.9 5.6

XC 504 XC 483 VC 466 VC 451 VC 438 VC 417 C 408 C 400 C 385 MR80-06

Nozzles

0.47 25 14 80° 0.52 30 15 -06 0.56 35 17 0.60 40 18 0.64 45 19 0.67 50 20 0.73 60 22 0.76 65 23 0.79 70 24 0.85 80 25

0.50 40 15 12 10 8 7.4 5.9 0.53 45 16 13 11 9 8 6.3 0.56 50 17 13 11 9 8 6.6

0.61 60 18 15 12 10

0.64 65 19 15 13 11

0.66 70 20 16 13 11

0.71 80 21 17 14 12 11 8 7 F 208 28% 95% M 258 16% 91% Flow Boom Application Speed (mph) @ ER80-06 (40270-06) SR80-06 (40288-06)

0.42 20 13

10 8 7 6.3 4.2 3.6 C

11 9 8 7.0 4.7 4.0 C

12 10 9 8 5.1 4.4 C

13 11 9 8 5.6 4.8 C

14 12 10 9 6 5.1 C

15 13 11 10 6 5.4 C

16 13 11 10 7 6 M 267 22% 90% C 368 8% 86% 17 15 12 11 7 6 M 257 24% 90% C 351 9% 88% 18 15 13 11 8 7 M 253 25% 90% C 344 9% 89% 19 16 13 12 8 7 M 249 26% 90% C 337 10% 89% 20 17 14 13 8 7 M 242 27% 90% C 326 10% 90%

Flow us gpm

Application Speed (mph) @

psi 15Gpa 18Gpa 20Gpa 25Gpa 30Gpa 40Gpa 50Gpa Class VMD <141 <600 Class VMD <141 <600 Class VMD

Boom

0.79 25 16 13

12 9 13 10 14 11 15 12 16 13 17 13 18 15 19 15 20 16 21 17

8 6 5 9 6 5 9 7 6 10 7 6 11 8 6 11 8 7 12 9 7 13 10 8 13 10 8 14 11 8

XC 428 10% 80% UC 537 6% 50% XC 405 12% 82% UC 512 7% 55% VC 386 13% 83% UC 490 7% 59% C 371 14% 84% XC 472 8% 63% C 358 15% 85% XC 455 8% 65% C 346 16% 86% XC 441 9% 67% M 328 18% 87% XC 415 10% 71% M 320 18% 87% XC 404 10% 72% M 313 19% 88% XC 394 10% 74% F 300 20% 89% VC 375 11% 76%

40

17 15 12

17 16 13

19 17 13 11 10

9 7 6.1 M 224 25% 95% C 296 14% 89% 10 8 6.3 M 220 26% 95% C 286 14% 89% 10 8 6.5 F 215 26% 95% C 276 15% 90%

us gpm psi 10Gpa 12.5Gpa 15Gpa 18Gpa 20Gpa 30Gpa 35Gpa Class VMD <141 <600 Class VMD <141 <600 Class VMD

Application Speed (mph) @ ER80-08 (40270-08) SR80-08 (40288-08)

us gpm psi 15Gpa 18Gpa 20Gpa 25Gpa 30Gpa 35Gpa 40Gpa Class VMD <141 <600 Class VMD <141 <600 Class VMD

Flow Boom

0.57 20 11 9 8 7 6 4.8 4.2 VC 367 12% 86%

0.63 25 80° 0.69 30 -08 0.75 35 0.80 40 0.85 45 0.89 50 0.98 60 1.02 65 1.06 70 1.13 80

13 14 15 16 17 18 19 20 21 22

10 9 8 6 11 10 8 7 12 11 9 7 13 12 10 8 14 13 10 8 15 13 11 9 16 15 12 10

5 4.7 C 338 15% 89% UC 516 7% 54%

10

10 9

6 6 7 7 8 8 9

5 C 317 17% 90% UC 490 8% 59%

UC 540 UC 518 UC 500 UC 484 XC 470 XC 448 XC 438 XC 430 VC 415 MR80-10

6 6 6 7 7 8 8 8

Distributed By: Sensor-1 • 202 Main Street, Princeton, KS 66078 • 1-800-SENSOR-1