Page 189 - PUC 2017 Master Catalog

P. 189

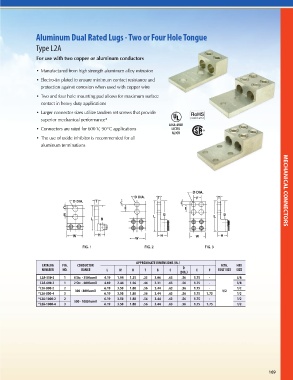

Aluminum Dual Rated Lugs - Two or Four Hole Tongue

Type L2A

For use with two copper or aluminum conductors

• Manufactured from high strength aluminum alloy extrusion

• Electro-tin plated to ensure minimum contact resistance and

protection against corrosion when used with copper wire

• Two and four hole mounting pad allows for maximum surface

contact in heavy duty applications

• Larger connector sizes utilize tandem set screws that provide

superior mechanical performance*

486A-486B

486B

• Connectors are rated for 600 V, 90°C applications LISTED

LISTED

AL9CU

AL9CU

• The use of oxide inhibitor is recommended for all

aluminum terminations

T D DIA. MECHANICAL CONNECTORS

D DIA.

D DIA.

D DIA.

T

T D DIA. D DIA. F T D DIA. D DIA. T F F D DIA. D DIA. F D DIA. D DIA. F F

T

F F

F

T

D DIA.

T D DIA. D DIA. D DIA. D DIA. D DIA. D DIA. T D DIA. D DIA. C T C C

C

D DIA.

T

F F F T F C F D DIA. F C C D DIA. C

C C C C C C C C E C C E E C E C E

E E E

E E E E E E L B E E E E L B L L B B E L B E L B L L L

L B L B L B L L B L B L L L B

W W W W W W W W W

W

H W WH W W H W W W W W W W H W H W W W W H W H H W W W W H W W

H W W H W W H W W

FIG. 4

FIG. 2

FIG. 3

FIG. 1 FIG. 2 FIG. 1 FIG. 3 FIG. 2 FIG. 1 FIG. 5 FIG. 4 FIG. 3 FIG. 5 FIG. 4 FIG. 5

FIG. 1 FIG. 6 FIG. 7 FIG. 2 FIG. 97 FIG. 8 FIG. 7 FIG. 8 FIG. 9 FIG. 10 FIG. 11

FIG. 11

FIG.

FIG. 11 FIG. 10

FIG. 10

FIG. 6 FIG. 3 FIG. 9

FIG. 8

FIG. 6

APPROXIMATE DIMENSIONS (IN.)

CATALOG FIG. CONDUCTOR MTG. HEX

NUMBER NO. RANGE L W H T B C D E F BOLT SIZE SIZE

(DIA.)

L2A-350-2 1 6 Str. - 350 kcmil 4.19 1.94 1.25 .25 3.06 .63 .56 1.75 - 3/8

L2A-600-2 1 2 Str. - 600 kcmil 4.69 2.44 1.56 .44 3.31 .63 .56 1.75 - 3/8

*L2A-800-2 2 300 - 800 kcmil 6.19 3.50 1.88 .56 3.44 .63 .56 1.75 - 1/2 1/2

*L2A-800-4 3 6.19 3.50 1.88 .56 3.44 .63 .56 1.75 1.75 1/2

*L2A-1000-2 2 500 - 1000 kcmil 6.19 3.50 1.88 .56 3.44 .63 .56 1.75 - 1/2

*L2A-1000-4 3 6.19 3.50 1.88 .56 3.44 .63 .56 1.75 1.75 1/2

168 169