Page 17 - UNAM Virtual Graduation e-Book (April2021)

P. 17

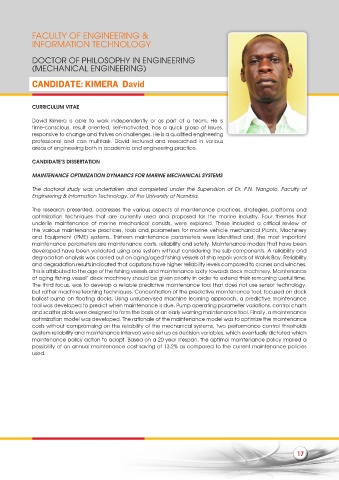

FACULTY OF ENGINEERING &

INFORMATION TECHNOLOGY

DOCTOR OF PHILOSOPHY IN ENGINEERING

(MECHANICAL ENGINEERING)

CANDIDATE: KIMERA David

CURRICULUM VITAE

David Kimera is able to work independently or as part of a team. He is

time-conscious, result oriented, self-motivated, has a quick grasp of issues,

responsive to change and thrives on challenges. He is a qualified engineering

professional and can multitask. David lectured and researched in various

areas of engineering both in academia and engineering practice.

CANDIDATE’S DISSERTATION

MAINTENANCE OPTIMIZATION DYNAMICS FOR MARINE MECHANICAL SYSTEMS

The doctoral study was undertaken and completed under the Supervision of Dr. F.N. Nangolo, Faculty of

Engineering & Information Technology, of the University of Namibia.

The research presented, addresses the various aspects of maintenance practices, strategies, platforms and

optimization techniques that are currently used and proposed for the marine industry. Four themes that

underlie maintenance of marine mechanical consists, were explored. These included a critical review of

the various maintenance practices, tools and parameters for marine vehicle mechanical Plants, Machinery

and Equipment (PME) systems. Thirteen maintenance parameters were identified and, the most important

maintenance parameters are maintenance costs, reliability and safety. Maintenance models that have been

developed have been validated using one system without considering the sub-components. A reliability and

degradation analysis was carried out on aging/aged fishing vessels at ship repair yards at Walvis Bay. Reliability

and degradation results indicated that capstans have higher reliability levels compared to cranes and winches.

This is attributed to the age of the fishing vessels and maintenance laxity towards deck machinery. Maintenance

of aging fishing vessel’ deck machinery should be given priority in order to extend their remaining useful time.

The third focus, was to develop a reliable predictive maintenance tool that does not use sensor technology,

but rather machine learning techniques. Concentration of the predictive maintenance tool, focused on dock

ballast pump on floating docks. Using unsupervised machine learning approach, a predictive maintenance

tool was developed to predict when maintenance is due. Pump operating parameter variations, control charts

and scatter plots were designed to form the basis of an early warning maintenance tool. Finally, a maintenance

optimization model was developed. The rationale of the maintenance model was to optimize the maintenance

costs without compromising on the reliability of the mechanical systems. Two performance control thresholds

(system reliability and maintenance interval) were set up as decision variables, which eventually dictated which

maintenance policy action to adopt. Based on a 20 year lifespan, the optimal maintenance policy implied a

possibility of an annual maintenance cost saving of 13.2% as compared to the current maintenance policies

used.

17