Page 53 - CAPE Green Engineering Syllabus 2016.docx_Neat

P. 53

The ethanol is removed from the fermentation mixture by fractional distillation while the carbon

dioxide is captured and processed.

The distillation process requires large amounts of heat and

produces huge amounts of liquid waste rich in organic

material called stillage or vinasse. The improper disposal

of this vinasse can have significant negative consequences

for the environment especially the waterways. The large

amounts of organic material lead to eutrophication and

unpleasant odours. To address this vinasse disposal issue

DDL has installed a biomethanisation plant which converts

the vinasse into biogas which is rich in methane and other

combustible gases. Since the biomethanisation process

coverts the organic material via bacterial processes the

organic load of the vinasse is reduced significantly and the

liquid waste is now rendered less harmful to the

environment. This waste may now be utilised as an

organic fertiliser.

Figure 2-Unique Wooden Still

(http://www.cocktailsoldfashioned.de/2011/02/demera

ra-distillers-limited-guyana-rum/ (accessed Oct 07, 2014)

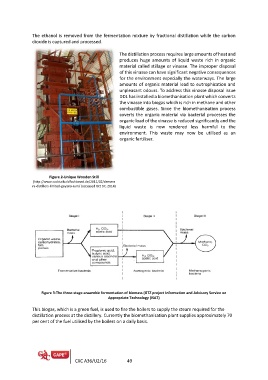

Figure 3-The three-stage anaerobic fermentation of biomass (GTZ project Information and Advisory Service on

Appropriate Technology (ISAT)

This biogas, which is a green fuel, is used to fire the boilers to supply the steam required for the

distillation process at the distillery. Currently the biomethanisation plant supplies approximately 70

per cent of the fuel utilised by the boilers on a daily basis.

CXC A36/U2/16 49