Page 157 - BlueFastening-Systems_Brochure_07192017

P. 157

Of course TORX PLUS® also provides

the well-known advantages that

distinguished the TORX® driver system.

Low axial forces required From this we derive the following

Fatigue-free working assembly advantages

No damage to surface

High breakaway torques • Downtime minimised due to longer tool life

No tool slippage • Improved assembly reliability between tightening and

breaking torques

• Screwing conditions improved with improved assembly

tool seating

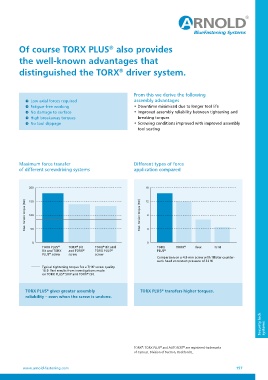

Maximum force transfer Different types of force

of different screwdriving systems application compared

200 16

Max. torsion torque (Nm)150 12

Max. torsion torque (Nm)

100 8

Security lock

50 systems4

0 0

TORX

TORX PLUS® TORX® Bit TORX® Bit and PLUS® TORX® Ihex Cr H

Bit and TORX and TORX® TORX PLUS®

PLUS® screw screw screw Comparison on a 4.8 mm screw with fillister counter-

sunk head at contact pressure of 23 N.

Typical tightening torque for a 7/16" screw quality

10.9. Test results from investigations made

on TORX PLUS® 50IP and TORX® t50.

TORX PLUS® gives greater assembly TORX PLUS® transfers higher torques.

reliability – even when the screw is undone.

TORX®, TORX PLUS® and AUTOSERT® are registered trademarks

of Camcar, Division of Textron, Rockford IL.

wwwww.war.naornldo-lfda-sftaesnteinngin.cgo.cmom 157 03