Page 9 - bitbook

P. 9

Performance Evaluation Report on Rural Roads Constructed Using CRRI-Bitchem Cold Mix in Different District of Assam during 2008-2009 2

1.2 Theory of Bitumen Emulsification

Bitumen, an immiscible liquid, may be dispersed in water phase by mechanical means but such dispersion is not

maintained third component which has special solubility characters. This additional component which promotes

emulsification and keeps the emulsion stable after formation, is commonly called an emulsifying agent.

Therefore, the physical and chemical properties of the emulsion are largely dependent on the chemical type and

molecular structure.

Many agents are electrolytes and dissociate in water in to anions (negative particles) and cations (positive

particles). Emulsions made with agents of anion active portion are anionic emulsions, and the emulsified droplet

bears a negative charge. If the active portion of the emulsifier is cationic, the agent is cationic active and

emulsions are cationic. In this case the emulsified droplets bear a positive charge. Some emulsifying agents do not

dissociate at all and are referred to as non-ionic agent.

When an emulsifying agent is placed in water, the molecule migrates to the surface and orients at the air-water

interface. The positive charge is attached to bitumen globule giving the cationic bitumen emulsion as positive

charge. The charge provides repulsive force among the particles, which provide the stability to the emulsion. The

cationic emulsion is technically superior than the anionic one as in cationic emulsion, water is dissociated due to

chemical reaction (neutralization) of positive charge of emulsion with negative charge of silicious aggregates).

1.3 Manufacturing Process of Bitumen Emulsion

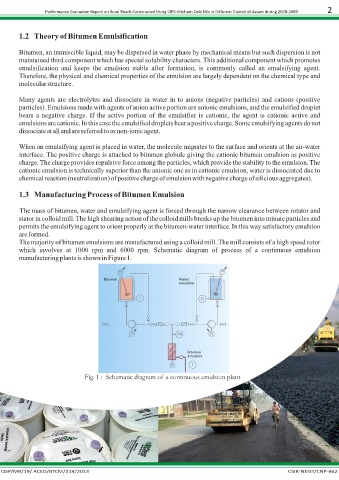

The mass of bitumen, water and emulsifying agent is forced through the narrow clearance between rotator and

stator in colloid mill. The high shearing action of the colloid mills breaks up the bitumen into minute particles and

permits the emulsifying agent to orient properly at the bitumen-water interface. In this way satisfactory emulsion

are formed.

The majority of bitumen emulsions are manufactured using a colloid mill. The mill consists of a high speed rotor

which involves at 1000 rpm and 6000 rpm. Schematic diagram of process of a continuous emulsion

manufacturing plants is shown in Figure 1.

Fig. 1 : Schematic diagram of a continuous emulsion plant

QSP/MR/19/ ACED/BTCM/214/2013 CSIR-NEIST/CNP-462